OUR CAPABILITIES

Custom Injection Molded Parts

Customized injection molded parts are components designed and manufactured according to specific needs. They have high flexibility in design and material selection, and are suitable for applications in industries such as LED lighting, electronic products, and electrical products. Whether produced in small or large quantities, customized injection molded parts can meet diverse needs.

Multi-Shot Injection Molding

Multi shot injection molding is an advanced manufacturing process that can combine multiple materials or colors into a single part in one production cycle. This technology can achieve complex design, enhance functionality, and reduce assembly steps, and is widely used in household appliances, hardware tools, and other fields, especially suitable for products that require multi material integration.

Injection Molded Plastic Parts

Injection molded plastic products are components formed into specific shapes and sizes by injecting molten plastic into molds. This process supports multiple materials and designs, suitable for a wide range of fields from LED lighting, electronic products, medical equipment, sports equipment to industrial equipment. Its characteristics are high efficiency, accuracy, and scalability

High-Volume Injection Molded Parts

Mass injection molded parts are components designed for efficient and low-cost production. Manufacturing through high-speed production processes ensures consistent quality and scalability, suitable for industries such as packaging, construction, toys, etc. This type of component is very suitable for application scenarios that require high output and durability.

Injection Molded Parts Manufacturer

InjectionMolded. Parts is a Chinese manufacturer specializing in the field of injection molding. Our company is committed to providing one-stop solutions for customized injection molded parts, high-volume injection molded parts, multi shot injection molded components, and injection molded plastic products to global customers.

Our company is equipped with multi-shot / multi-color injection molding machines, high-speed precision injection molding machines and other equipment, which can meet various injection molding needs from simple to complex. Especially in the field of multi shot molding technology, We have accumulated rich experience and can achieve precise combination of multiple materials, creating products with higher added value for customers. In terms of quality management, we strictly follow the ISO 9001 and ISO 14001 standards, and have established a full process quality assurance system from mold design, material selection to production process control and finished product inspection. Each batch of products undergoes strict testing and inspection to ensure compliance with customer technical requirements and industry standards.

Our Capabilities:

We have multiple automated production lines equipped with multi station multi-color injection molding machines, high-speed precision injection molding machines, and intelligent production equipment, which can achieve full-size coverage of injection molded parts from micro (0.1mm ³) to large (over 100L), meeting the customized needs of customers in industries such as LED lighting, electronic products, electrical products, medical, hardware and home appliances for different specifications of plastic products. Through modular production line layout, stable delivery of tens of thousands of injection molded parts per day can be achieved. We are particularly skilled in providing customers with efficient manufacturing solutions for large-scale standardized injection molded components and complex structured plastic products. For special needs, Our company can flexibly allocate resources from multiple production lines to quickly respond to customers’ trial production and mass production needs for small batches and multiple batches of products.

Based on our independently developed precision mold design capabilities and material modification technology, we are able to produce micro precision components with an accuracy of ± 0.01mm and thin-walled products with a wall thickness uniformity of ≤ 0.1mm. At the same time, we achieve integrated manufacturing of multi material composite through multi shot molding technology.

Our Independent Mold Workshop

We have an independent modern mold workshop equipped with five axis linkage machining centers, electric discharge molding machines, and precision testing equipment, which can achieve independent control of the entire process from 3D design, mold development to rapid sampling, significantly shortening project cycles and reducing customer costs. Relying on its independent mold manufacturing capabilities, We have achieved a 30% reduction in mold development cycle compared to the industry average, and has effectively improved injection molding production efficiency by over 20% through optimized mold structure design.

In the injection molding production process, we integrate the advantages of mold self supply and establish a collaborative mechanism of “mold design injection molding”. By using Moldflow technology to predict molding defects and combining it with an online cavity pressure monitoring system, dynamic optimization of injection parameters is achieved to ensure a stable product qualification rate of over 99.8%. For customer customization needs, the mold workshop can quickly respond to design changes and support seamless switching between small batch trial molds and mass production molds.

OUR SERVICES

Rapid Prototyping

For customers who require rapid validation of product designs, we can provide efficient, flexible, and high-quality solutions by offering rapid prototyping services using 3D printing technology. Produce prototypes in small batches through rapid prototyping technology. Assist customers in verifying the feasibility of the design before formal production.

Production and Technical Support

Injection molding is the core service of injection molding factories. By heating and melting plastic particles or powders, injecting them into the mold, and cooling them to form the desired product shape. We not only provide production services, but also offer technical consultation to customers, including optimization of injection molding processes. Mold maintenance and upkeep. Suggestions for improving production efficiency. Resolve technical issues in production.

Secondary Processing

After injection molding, products usually require secondary processing to meet the final needs of customers. Common secondary processing includes surface treatment such as spraying, electroplating, screen printing, heat transfer printing, etc., to enhance the appearance and functionality of the product. Post processing: cutting, welding, polishing, assembly, etc., to bring the product to its final usable state.

Products Showcase

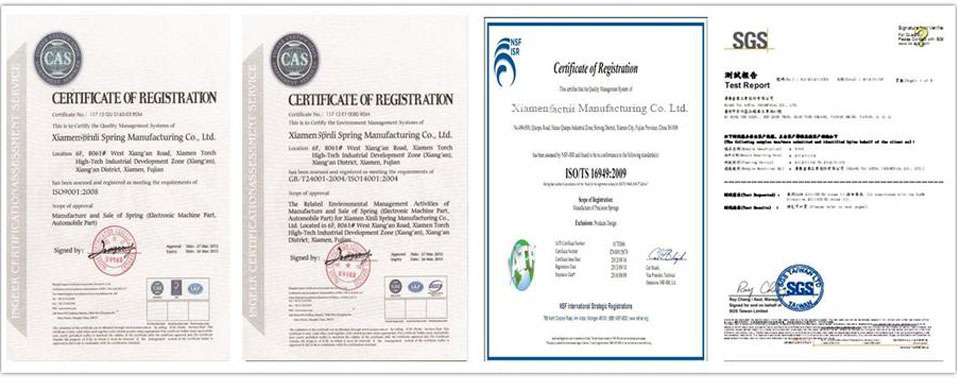

OUR CERTIFICATES