Advanced Manufacturing Capabilities for Superior Injection Molded Components

As a China-based injection molding supplier, we take pride in our state-of-the-art manufacturing facilities that enable us to produce high-quality injection molded components for global clients. Our factories are equipped with over 200 advanced injection molding machines, ranging from 50-ton to 1,500-ton clamping forces, allowing us to handle projects of all sizes—from small precision parts like medical device components to large automotive panels. We’ve invested heavily in automation, with robotic arms integrated into 80% of our production lines to ensure consistent part quality and reduce human error. Our in-house tooling department, staffed by experienced engineers, designs and manufactures custom molds using CAD/CAM software and CNC machining centers, ensuring that every mold is optimized for efficiency and precision. This vertical integration—controlling both mold making and production—allows us to deliver injection molded components with tight tolerances (as low as ±0.001mm) and complex geometries that meet the most demanding industry standards, whether for aerospace, electronics, or consumer goods.

Cost-Effective Production of Injection Molded Components Without Compromising Quality

We understand that competitive pricing is a key factor for our clients, which is why we’ve refined our production processes to deliver cost-effective injection molded components without sacrificing quality. Our scale of operations—producing over 50 million parts monthly—allows us to leverage economies of scale, reducing material and labor costs that we pass on to our customers. We’ve also established long-term partnerships with local material suppliers, securing bulk discounts on high-performance polymers like ABS, polypropylene, and engineering resins, which further lowers production costs. Additionally, our lean manufacturing practices, inspired by Six Sigma and 5S principles, minimize waste in every step of the process—from material handling to post-production inspection. This efficiency not only reduces costs but also shortens lead times, with most projects completed in 4-6 weeks compared to the industry average of 8-12 weeks. By balancing cost and quality, we ensure that our injection molded components offer the best value in the market, helping our clients stay competitive in their respective industries.

Rigorous Quality Control Ensuring Reliable Injection Molded Components

Quality is non-negotiable in our approach to producing injection molded components, and we’ve implemented a comprehensive quality control system that meets international standards such as ISO 9001, IATF 16949, and ISO 13485. From the moment raw materials arrive, we conduct strict incoming inspections, testing for purity, melt flow rate, and mechanical properties to ensure they meet our specifications. During production, our quality team uses advanced testing equipment—including coordinate measuring machines (CMM), optical comparators, and tensile testers—to monitor critical dimensions and performance metrics at every stage. We also perform 100% visual inspections on all injection molded components, checking for defects like flash, warpage, or surface imperfections. For clients in regulated industries, such as automotive and medical, we provide full traceability documentation, including material certificates, inspection reports, and process parameters. This commitment to quality has earned us the trust of global brands, who rely on our injection molded components to perform reliably in their products.

Streamlined Supply Chain for Efficient Delivery of Injection Molded Components

Our strategic location in China—with proximity to major ports in Shanghai, Shenzhen, and Ningbo—gives us a logistical advantage in delivering injection molded components to clients worldwide. We’ve built a streamlined supply chain that integrates raw material sourcing, production, and shipping, ensuring on-time delivery even for large or urgent orders. Our warehouse facilities, spanning over 50,000 square meters, are equipped with inventory management systems that track every batch of injection molded components, allowing us to fulfill orders quickly and accurately. We work with trusted logistics partners to offer flexible shipping options—air freight for urgent deliveries, sea freight for cost-effective bulk shipments, and rail transport for clients in Europe and Central Asia. Additionally, our sales and customer service teams, fluent in English, German, and Spanish, provide real-time updates on order status, addressing any concerns promptly. This focus on efficiency and communication ensures that our clients receive their injection molded components when and where they need them, minimizing downtime and keeping their production lines running smoothly.

Custom Solutions and Technical Expertise for Tailored Injection Molded Components

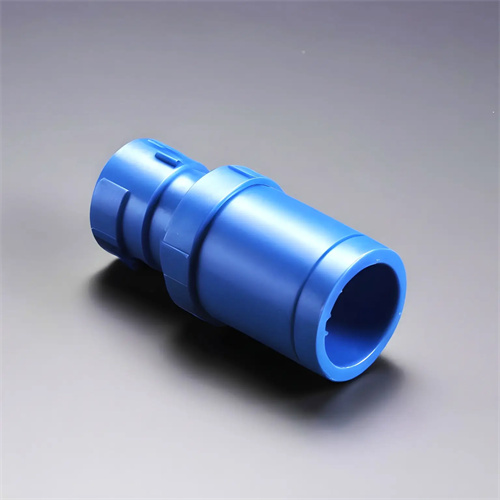

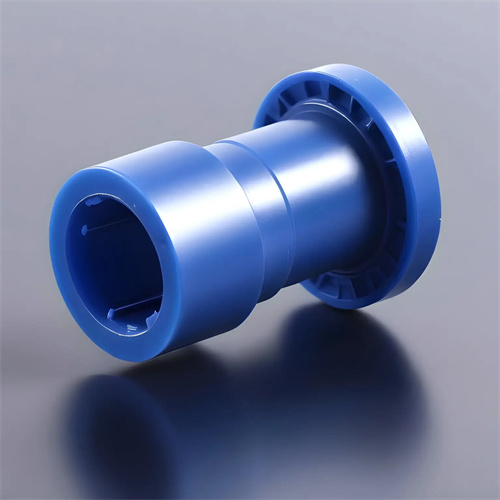

We believe that every client has unique needs, which is why we offer custom injection molding solutions to produce tailored injection molded components that meet specific design requirements. Our team of 50+ engineers—specializing in material science, mold design, and process engineering—collaborates with clients from the early stages of product development, providing design for manufacturability (DFM) analysis to optimize part designs for cost and performance. Whether clients need components with special finishes (such as textured surfaces or overmolding), or made from exotic materials (like PEEK or liquid silicone rubber), we have the expertise to deliver. We also invest in research and development, testing new materials and processes to expand our capabilities—recently adding micro-molding and multi-shot molding to our service offerings. This technical expertise, combined with our willingness to adapt to client needs, allows us to produce injection molded components that are not only high-quality but also perfectly suited to their intended application.

Global Partnerships Built on Trust with Injection Molded Components

Over the past 20 years, we’ve built long-term partnerships with clients in over 30 countries, based on a foundation of trust, quality, and reliability in our injection molded components. Many of our clients—from small startups to Fortune 500 companies—have chosen to work with us for decades, citing our consistent quality, competitive pricing, and responsive service as key factors. We’ve partnered with automotive manufacturers to produce interior and exterior components, with electronics companies to make precision parts for smartphones and appliances, and with medical device firms to create sterile, biocompatible components. We also support emerging industries, such as renewable energy, by producing custom parts for solar panels and wind turbines. These partnerships are built on transparency—we invite clients to visit our facilities, audit our processes, and participate in quality reviews—to ensure they’re confident in our capabilities. As we look to the future, we’re committed to expanding our global reach while maintaining the high standards that have made us a trusted China-based injection molding supplier, delivering injection molded components that drive our clients’ success.