Micro-Tolerance Manufacturing for Ultra-Precise Injection Molded Plastics

We specialize in producing precision plastic components with microscopic tolerances, where even a 0.001mm deviation can affect performance, making injection molded plastics indispensable in critical applications. Our micro-injection molding machines, equipped with servo-driven systems, deliver material in nanogram increments, ensuring consistent filling of tiny cavities—some as small as 0.5mm in diameter. For example, a medical micro-valve component requiring a tolerance of ±0.0005mm is produced using our ultra-precision process, where mold temperatures are controlled to within ±0.1°C to prevent warping. We also use specialized tooling with diamond-polished surfaces to eliminate friction-related defects in injection molded plastics, ensuring smooth movement in parts like micro-gears for robotics. This level of precision transforms injection molded plastics from simple components to high-performance elements that enable the functionality of advanced devices.

Material Science Enabling Micro-Tolerance Injection Molded Plastics

The right materials are critical for achieving microscopic tolerances in precision injection molded plastics, as even minor shrinkage can compromise accuracy. We select low-shrinkage polymers like PEEK and acetal, which maintain dimensional stability within 0.05% of mold dimensions, ideal for components such as optical connectors with tight mating requirements. For high-stress applications, we use glass-filled variants with controlled fiber orientation to minimize anisotropic shrinkage—our aerospace clients rely on these injection molded plastics for sensor housings that must align with metal components within 0.002mm. We also test material behavior under varying conditions: a client’s automotive micro-switch required injection molded plastics that maintained tolerances from -40°C to 125°C, so we formulated a custom polyamide blend that passed 5,000 thermal cycles without exceeding dimensional limits. By pairing materials with precision processing, we ensure injection molded plastics meet microscopic tolerance demands.

Advanced Metrology for Verifying Precision in Injection Molded Plastics

Verifying microscopic tolerances in injection molded plastics requires metrology tools that can measure at the sub-micron level, ensuring every component meets specifications. Our quality lab features coordinate measuring machines (CMMs) with laser scanning capabilities that capture 10 million data points per second, creating 3D models of injection molded plastics to compare against CAD designs. For internal features, we use computed tomography (CT) scanning, which reveals hidden dimensions—like the wall thickness of a micro-fluidic channel—injection molded plastics used in diagnostic devices. We also employ optical comparators with 500x magnification to inspect surface finishes, ensuring no burrs or scratches exceed 0.001mm in height. A recent project for a semiconductor client required 100% inspection of injection molded plastics with 0.003mm pin spacing; our automated vision system checked each part in 2 seconds, maintaining throughput while ensuring precision. This rigorous metrology gives clients confidence in the reliability of our precision injection molded plastics.

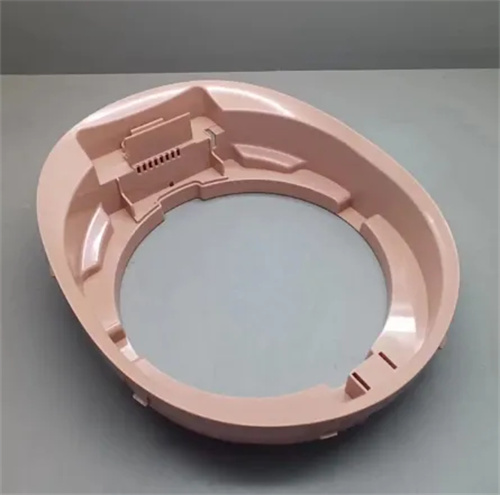

Industry Applications Where Micro-Tolerance Injection Molded Plastics Shine

Precision injection molded plastics with microscopic tolerances are driving innovation in industries where small deviations can have massive consequences. In medical devices, our micro-molded components—like the 0.3mm-diameter nozzles in insulin pens—ensure accurate drug delivery, with tolerances that directly impact patient dosage. The electronics sector relies on our injection molded plastics for connector pins with 0.002mm positional accuracy, enabling the miniaturization of smartphones and wearables. Aerospace applications use our precision injection molded plastics in gyroscope housings, where 0.001mm misalignment would compromise navigation systems. Even consumer goods benefit: our micro-tolerance injection molded plastics in camera lenses ensure sharp imagery by maintaining lens spacing within 0.005mm. These applications prove that the massive impact of precision injection molded plastics stems from their ability to meet microscopic tolerance requirements.

Process Control for Consistency in High-Volume Precision Injection Molded Plastics

Maintaining microscopic tolerances across high-volume production of injection molded plastics requires process control systems that minimize variation. We use closed-loop feedback systems that adjust injection pressure and speed 1,000 times per second, compensating for material viscosity changes in real time. Our molds feature active cooling zones with individual temperature control, ensuring uniform solidification of injection molded plastics—critical for a client producing 1 million micro-gear components monthly with ±0.001mm tooth thickness tolerance. We also implement statistical process control (SPC), analyzing data from every 100th part to detect trends before they affect tolerances. For example, a shift in ambient temperature was identified as causing 0.0008mm deviations in injection molded plastics; our system automatically adjusted mold cooling, preventing scrap. This level of control ensures that even at high volumes, injection molded plastics maintain microscopic tolerances.

The Ripple Effect of Micro-Tolerance Injection Molded Plastics

The massive impact of precision injection molded plastics extends beyond their immediate functionality, creating ripple effects that drive broader innovation. By achieving microscopic tolerances, we enable product miniaturization—medical devices that are less invasive, electronics that are more portable, and machinery that uses less energy. Our precision injection molded plastics reduce assembly time: a client’s industrial robot, which once required 2 hours of manual alignment, now uses our drop-in injection molded plastics with 0.003mm tolerances, cutting assembly to 15 minutes. They also improve reliability: aerospace clients report 50% fewer failures after switching to our tolerance-controlled injection molded plastics, reducing maintenance costs. Even sustainability benefits—lighter, smaller products made with precision injection molded plastics consume fewer resources and generate less waste. This ripple effect proves that microscopic tolerances in injection molded plastics create impacts far larger than their size.