Material Compatibility in Multi-Shot Injection Molding for Dual-Material Parts

We specialize in identifying and leveraging material compatibility to ensure perfect bonding in dual-material multi-shot injection molding, even with seemingly dissimilar plastics. Our material scientists analyze key factors like melt flow rates, chemical affinity, and thermal expansion coefficients to pair materials that form strong, durable bonds. For example, we successfully bond polypropylene (PP) with thermoplastic elastomers (TPEs) by selecting TPE formulations with maleic anhydride grafting, which chemically reacts with PP’s polymer chains during multi-shot injection molding. Another common pairing—ABS and PC—benefits from their similar molecular structures, creating a mechanical interlock when molded in sequence. We also test compatibility through small-batch trials, ensuring that combinations like nylon and silicone form bonds that withstand 100+ thermal cycles without delamination. This focus on material science ensures our dual-material multi-shot injection molding parts achieve bond strengths exceeding 200 psi, meeting the most demanding application requirements.

Process Optimization in Multi-Shot Injection Molding for Strong Bonds

Our multi-shot injection molding processes are fine-tuned to maximize bond strength between dissimilar plastics, turning material compatibility into reliable adhesion. We control variables like mold temperature (typically 80-120°C for the first material) to ensure the substrate remains slightly molten when the second material is injected, promoting molecular diffusion at the interface. Injection pressure and speed are also optimized—higher pressure (1500-2000 psi) for the second material ensures it fills micro-voids on the first material’s surface, creating a mechanical lock. For example, bonding rigid PBT with flexible TPU requires a 30% higher second-shot pressure than bonding similar materials, a parameter we identified through iterative testing. We also use sequential valve gating to control the second material’s flow path, preventing premature cooling before it contacts the substrate. These process adjustments ensure that even challenging pairs, like HDPE and EPDM, achieve consistent bond strength in multi-shot injection molding.

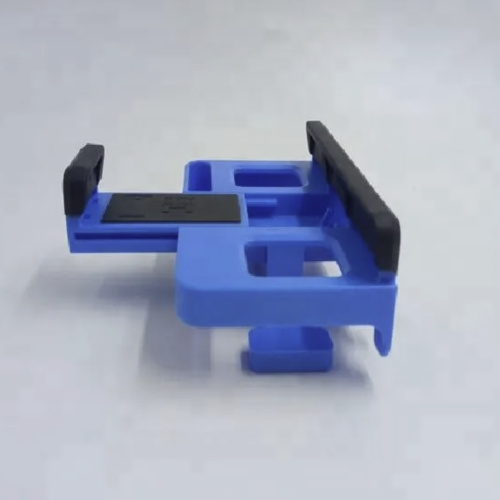

Design Features Enhancing Bonding in Multi-Shot Injection Molding

We integrate specific design features into dual-material parts to enhance bonding in multi-shot injection molding, complementing material and process optimizations. Mechanical interlocks—such as grooves, ribs, or textured surfaces on the first material—increase the contact area by 30-50%, giving the second material more surface to grip. For example, a tool handle design includes 0.5mm-deep circumferential grooves in the PP core, which the TPE overmold fills completely, creating a bond 40% stronger than a smooth surface. We also design with gradual material transitions, avoiding sharp corners that can trap air or cause uneven cooling. A medical device housing uses a tapered edge where PC meets TPE, ensuring uniform pressure distribution during multi-shot injection molding. These design elements, combined with our process expertise, ensure dual-material parts maintain perfect bonds even under stress.

Testing and Validation of Bonds in Multi-Shot Injection Molding

Rigorous testing validates that our dual-material multi-shot injection molding parts achieve perfect bonds, withstanding real-world conditions. We perform peel tests (ASTM D3167) to measure bond strength, requiring results of at least 150 psi for structural components. Shear tests (ASTM D1002) simulate lateral forces, ensuring bonds hold under loads up to 500N for automotive parts. Environmental testing—including thermal cycling (-40°C to 120°C), humidity exposure (95% RH for 1000 hours), and chemical immersion—verifies bond integrity after aging. A recent validation for a consumer electronics case (ABS + TPE) showed no delamination after 5000 flex cycles, exceeding the client’s requirement of 3000 cycles. We also use ultrasonic testing to inspect internal bond quality, identifying any voids or weak points invisible to the naked eye. This comprehensive testing ensures multi-shot injection molding bonds perform as reliably as the materials themselves.

Industry Applications of Dual-Material Multi-Shot Injection Molding

Dual-material multi-shot injection molding solves unique challenges across industries, with perfectly bonded dissimilar plastics enabling innovative designs. In automotive, we produce door handles with PP cores and TPE grips that withstand 100,000+ actuations without separation, improving durability and user comfort. Medical devices use PC/TPE combinations for diagnostic tool housings, where the rigid core provides structural support and the soft overmold ensures a comfortable, secure grip. Consumer goods benefit from ABS/TPU parts like toothbrush handles, where the hard core resists bending and the soft overmold prevents slippage. Even industrial equipment uses our dual-material parts—like nylon/PTFE bearing housings, where the bond between rigid structural material and low-friction surface eliminates the need for adhesives. These applications demonstrate that multi-shot injection molding makes perfect bonding between dissimilar plastics not just possible, but practical for mass production.

Advantages Over Assembly in Multi-Shot Injection Molding

Dual-material multi-shot injection molding offers significant advantages over assembling separate plastic parts, with perfect bonding eliminating the limitations of mechanical fasteners or adhesives. Bonded parts weigh 10-15% less than those with screws or clips, improving efficiency in applications like aerospace components. Production time is reduced by 30-50%—a dual-material gearshift knob produced in one multi-shot cycle replaces a 3-step assembly process of molding, adhesively bonding, and curing. Quality is also enhanced: bonded parts have no gaps where contaminants can accumulate, critical for food-contact items like blender grips. A client producing child safety seats switched from assembled PP and TPE parts to multi-shot injection molding, reducing defect rates from 4% to 0.3% and cutting per-unit costs by 22%. These benefits make multi-shot injection molding the superior choice for creating dual-material parts with perfect bonds.