In the ever – evolving and complex construction industry, custom injection molded parts have emerged as indispensable elements, redefining the boundaries of what is possible in building design, construction, and maintenance. These precisely engineered components are not merely parts but catalysts for innovation, significantly enhancing the functionality, durability, and sustainability of modern structures. As we strive to meet the diverse and stringent demands of contemporary construction projects, custom injection molding technology offers us a versatile toolkit to create buildings that are efficient, safe, and aesthetically stunning.

1. Fortifying Structural Integrity with Custom Injection Molded Parts

Custom injection molded parts play a crucial role in reinforcing the structural stability of buildings across various scales. In large – scale commercial high – rises, we utilize custom – molded composite connectors to join steel beams and columns. These connectors, often crafted from fiber – reinforced polymers, are designed with precision – engineered geometries that ensure a snug fit. For example, in the construction of a skyscraper in a bustling city center, the custom injection molded connectors can bear loads of up to several tons, providing a secure connection while reducing the overall weight of the structural framework by as much as 30% compared to traditional metal connectors. This weight reduction not only eases the construction process but also enhances the building’s energy efficiency by reducing the load on its foundation and supporting systems.

In bridge construction, custom injection molded dampers are increasingly being integrated into the structure. These dampers are made from high – performance elastomeric polymers that can effectively absorb and dissipate the energy generated by traffic vibrations and seismic activities. In earthquake – prone regions, such as California, custom injection molded seismic dampers installed in bridges have been proven to reduce the amplitude of vibrations by up to 60%, significantly improving the bridge’s resilience and extending its service life.

2. Boosting Energy Efficiency with Custom Injection Molded Parts

Energy efficiency is a top priority in modern construction, and custom injection molded parts offer innovative solutions in this regard. In the insulation systems of buildings, custom – molded plastic insulation clips are essential components. These clips are typically made from low – thermal – conductivity plastics, such as polypropylene with added thermal – barrier additives. When securing insulation materials like fiberglass or mineral wool to the building envelope, these clips create a thermal break, preventing heat transfer through the fastening points. In a residential building, the use of these custom injection molded insulation clips can reduce heat loss by up to 15%, leading to significant savings in heating costs during the winter months.

For ventilation systems, custom injection molded air ducts are a game – changer. With smooth inner surfaces achieved through precise molding techniques, these ducts minimize air resistance. Compared to traditional sheet – metal ducts, custom injection molded air ducts can reduce air friction losses by up to 20%, enabling more efficient air flow. This improvement in efficiency means that ventilation systems can operate with smaller, less energy – consuming fans, resulting in overall energy savings of around 10 – 15% for the building’s HVAC system.

3. Achieving Cost – effectiveness with Custom Injection Molded Parts

In the highly competitive construction market, cost – effectiveness is key, and custom injection molding provides practical and efficient solutions. For large – scale residential construction projects, such as housing developments with hundreds of units, the mass – production capabilities of custom injection molding shine. Take the production of electrical outlet covers as an example. Once the mold is developed, we can produce thousands of identical outlet covers in a short period. The cost per unit for a custom injection molded outlet cover can be as low as \(0.50, compared to \)1.50 – $2.00 for a similar cover produced through traditional manufacturing methods.

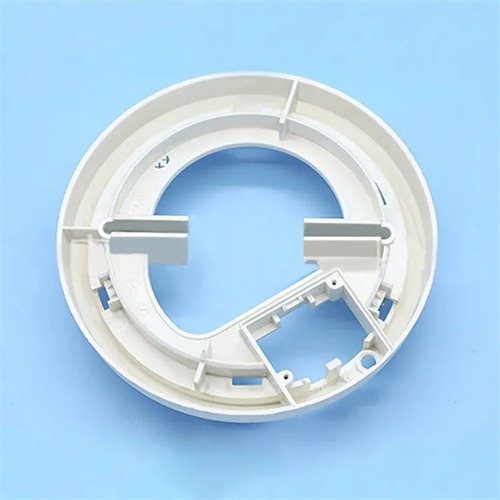

Moreover, custom injection molding allows for the integration of multiple functions into a single part, streamlining the construction process. In plumbing systems, custom – molded plastic connectors can combine the functions of sealing, joining, and flow control. These multi – functional connectors eliminate the need for additional components and complex assembly steps, reducing labor costs by approximately 20%. For a large – scale commercial building project, these cost savings can amount to tens of thousands of dollars, making custom injection molded parts an attractive option for cost – conscious developers.

4. Elevating Aesthetic Design with Custom Injection Molded Parts

The aesthetic appeal of a building is as important as its functionality, and custom injection molded parts offer unparalleled design flexibility. In architectural facades, custom – molded plastic panels can be used to create intricate and unique designs. For instance, in a contemporary art museum, custom injection molded panels with a textured, 3D – like surface can be used to mimic natural elements such as rock formations or flowing water. These panels can be colored using advanced pigment – blending techniques, allowing for a wide range of hues, from vibrant and bold colors to subtle and earthy tones.

Inside buildings, custom injection molded decorative elements add a touch of elegance. Custom – molded ceiling medallions, for example, can be designed with elaborate patterns and motifs, enhancing the grandeur of a room. These medallions can be made from lightweight yet durable plastics, making them easier to install compared to traditional plaster or metal counterparts. In a luxury hotel lobby, custom injection molded ceiling medallions can create a focal point, elevating the overall aesthetic of the space and leaving a lasting impression on guests.

5. Promoting Sustainability with Custom Injection Molded Parts

Sustainability is at the forefront of the construction industry’s agenda, and custom injection molded parts contribute significantly to green building practices. Many plastics used in custom injection molding are recyclable. For example, polycarbonate, a commonly used material for custom injection molded parts in construction, can be recycled multiple times without significant loss of quality. When a building undergoes renovation or demolition, custom injection molded polycarbonate parts such as window frames or railing components can be collected, recycled, and reused in new construction projects, reducing the demand for virgin materials.

Furthermore, the use of bio – based plastics in custom injection molding is on the rise. Bio – based plastics, derived from renewable resources like corn starch or sugarcane, have a lower environmental impact compared to traditional fossil – fuel – based plastics. In the construction of a sustainable office building, custom injection molded parts made from bio – based plastics can be used for interior components such as desk accessories or partition panels. These parts not only reduce the building’s carbon footprint but also showcase the developer’s commitment to environmental sustainability, appealing to eco – conscious tenants and investors.