In the dynamic and evolving construction industry, multi – shot injection molding has emerged as an innovative solution, enabling us to produce construction components that integrate diverse materials, functions, and aesthetic elements. By leveraging the precision and versatility of this advanced molding process, we can create high – performance parts that meet the complex demands of modern construction projects, from enhancing building durability to optimizing energy efficiency. Multi – shot injection molding is not only revolutionizing the way we manufacture construction materials but also driving the industry towards more sustainable and intelligent building practices.

1. The Core Competencies of Multi – Shot Injection Molding for Construction

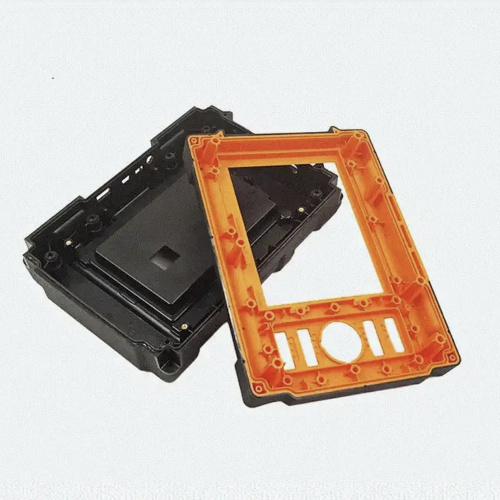

When we engage in construction projects, the application of multi – shot injection molding is driven by its unique capabilities. This technology allows us to inject two or more distinct materials, such as different types of plastics, composites, or even combinations of polymers and additives, into a single mold in multiple stages. The sophisticated control systems of multi – shot injection molding machines enable us to precisely manage the injection sequence, temperature, pressure, and volume of each material, resulting in components with customized properties.

One of the key advantages is the ability to create parts with gradient properties. For instance, we can produce components that transition from a rigid outer layer for structural support to a softer inner layer for shock absorption or insulation. This eliminates the need for complex assembly processes that combine separate parts with different functions. Additionally, multi – shot injection molding offers unparalleled design freedom, allowing us to create intricate patterns, textures, and color combinations directly during the molding process, which is invaluable for architectural aesthetics in construction.

2. Multi – Shot Injection Molding in Architectural Façade Elements

In the realm of architectural design, multi – shot injection molding plays a significant role in the production of façade elements. We can use this technology to create cladding panels that combine both functionality and visual appeal. For example, by injecting a weather – resistant, high – strength plastic as the base layer, we ensure the durability and protection of the building exterior. Then, in subsequent shots, we can add a layer of translucent or colored plastic to create unique lighting effects or decorative patterns.

These multi – shot – molded façade elements can also incorporate additional features. We can integrate insulation materials within the panels during the molding process, improving the building’s energy efficiency. Moreover, the ability to create complex geometries means we can design façade elements that mimic natural textures like stone or wood, offering an eco – friendly alternative to traditional building materials. The seamless integration of different materials in a single panel reduces the risk of water infiltration and improves the overall structural integrity of the building envelope.

3. Multi – Shot Injection Molding for Structural Connectors and Fasteners

In construction, structural connectors and fasteners are crucial for ensuring the stability and safety of buildings. Multi – shot injection molding allows us to produce these components with enhanced performance. We can combine a rigid engineering plastic with high tensile strength for the main body of the connector, providing the necessary structural support. Then, overmold it with a soft elastomeric material to create a secure, vibration – dampening connection.

For example, in prefabricated building systems, multi – shot – molded connectors can be designed to fit precisely with other structural elements. The elastomeric layer not only ensures a tight seal but also absorbs shock and reduces noise transmission. This technology also enables us to create connectors with integrated anti – corrosion coatings or self – lubricating surfaces, extending their lifespan and reducing maintenance requirements. The precision of multi – shot injection molding ensures consistent quality and reliable performance of these essential structural components.

4. Cost – Effectiveness and Performance Gains of Multi – Shot Injection Molding in Construction

While multi – shot injection molding may require a higher initial investment in equipment and mold development compared to traditional manufacturing methods, it offers significant cost – effectiveness in the long run for construction projects. By producing components with multiple integrated functions in a single molding process, we eliminate the need for multiple production steps, assembly labor, and additional materials for secondary operations. This streamlines the supply chain and reduces overall production costs.

In terms of performance, multi – shot – molded construction components outperform their traditional counterparts. The optimized combination of materials results in parts with improved mechanical properties, such as higher strength – to – weight ratios and better resistance to environmental factors. For example, multi – shot – molded window frames that combine a rigid plastic frame with a weather – sealing elastomer perimeter can significantly reduce air leakage, improving the building’s energy efficiency and indoor comfort. The durability and reliability of these components also contribute to lower long – term maintenance costs for buildings.

5. Future Horizons of Multi – Shot Injection Molding in the Construction Industry

As we look towards the future, we are optimistic about the potential of multi – shot injection molding in the construction industry. With the increasing focus on sustainable construction, we anticipate the development of more eco – friendly material combinations for multi – shot molding, such as bio – based polymers and recycled plastics. These materials will not only reduce the environmental impact of construction but also open up new possibilities for creating green building products.

Advancements in digital design and automation technologies will further enhance the capabilities of multi – shot injection molding. We expect to see the integration of artificial intelligence and machine learning algorithms to optimize the molding process, predict component performance, and enable the production of more complex and customized construction components. Additionally, as the demand for smart buildings grows, multi – shot injection molding could be used to embed sensors, conductive materials, and other smart elements directly into construction components, paving the way for more intelligent and responsive building systems.