In the dynamic and technology – driven realm of electrical products, injection molded components have emerged as essential building blocks, revolutionizing the way we design, manufacture, and deliver innovative solutions. These precisely crafted elements, produced through advanced injection molding techniques, play a pivotal role in enhancing the functionality, durability, and safety of a wide range of electrical devices, from everyday household appliances to complex industrial equipment. As we strive to meet the ever – evolving demands of consumers and industries, injection molded components empower us to create high – quality electrical products that are both reliable and cost – effective.

1. Cost – effective Production with Injection Molded Components

Cost – effectiveness is a crucial factor in the competitive electrical product market, and injection molded components offer significant advantages. Once the mold is developed, mass production of injection molded components allows us to achieve economies of scale. For example, when manufacturing plastic housings for electrical switches and sockets, producing hundreds of thousands of units through injection molding can reduce the per – unit cost by up to 40% compared to small – batch production methods. The initial investment in mold creation, which may vary depending on complexity, can be recouped within a relatively short time as production volumes increase.

Injection molded components also enable the integration of multiple functions into a single part. In power adapters, a custom – molded casing can combine structural support, electrical insulation, and cable management features. This streamlines the production process, eliminating the need for additional assembly steps and reducing labor costs. By leveraging injection molded components, we can optimize production efficiency and offer electrical products at competitive prices, making advanced electrical solutions accessible to a broader market.

2. Quality Assurance of Injection Molded Components

Maintaining consistent quality is of utmost importance in the electrical product industry, and injection molded components are manufactured with precision to meet stringent standards. Advanced injection molding machines are equipped with sophisticated control systems that monitor and regulate parameters such as temperature, pressure, and injection speed with high accuracy. This ensures that each injection molded component has uniform dimensions, wall thickness, and material properties.

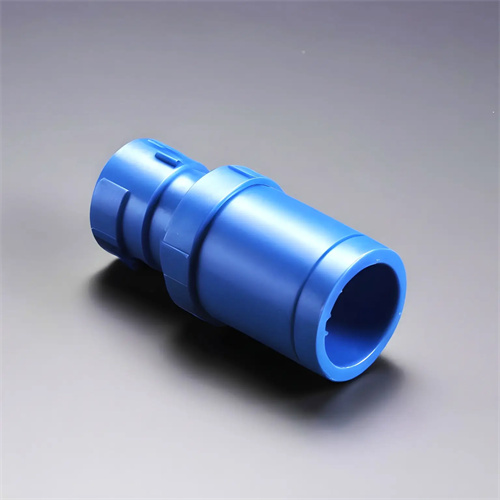

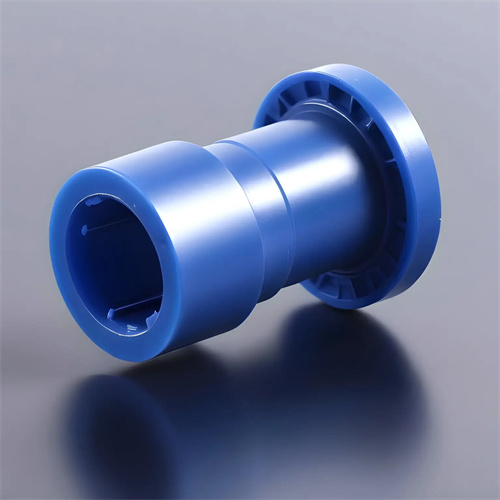

For instance, in the production of electrical connector housings, injection molding guarantees a precise fit for electrical contacts, ensuring reliable electrical connections. Automated inspection systems, using technologies like machine vision and infrared sensors, can detect any defects, such as voids, cracks, or dimensional inaccuracies, in real – time. Defective components are immediately removed from the production line, ensuring that only top – quality injection molded parts are used in the final assembly of electrical products. This strict quality control process not only enhances the reliability and lifespan of our products but also helps us comply with international safety and performance regulations.

3. Design Flexibility of Injection Molded Components

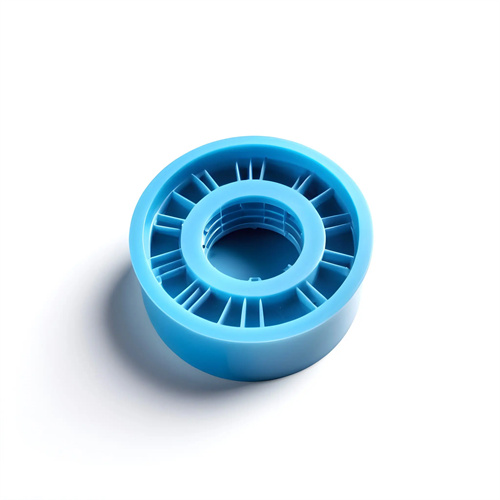

Injection molded components offer unparalleled design flexibility, enabling us to create electrical products with unique and innovative designs. With the help of computer – aided design (CAD) and computer – aided manufacturing (CAM) technologies, we can develop complex geometries, such as ergonomic shapes for appliance handles or intricate internal structures for electronic devices. In the design of modern smart home devices, injection molded components can be shaped to house sensors, control modules, and wireless communication components in a compact and aesthetically pleasing manner.

We also have a wide range of materials and finishes to choose from. Flame – retardant plastics are commonly used for electrical product housings to enhance safety, while materials with anti – static properties can be selected for components in sensitive electronic equipment. Surface treatments like texturing, painting, or applying a matte finish can be used to enhance the visual appeal of injection molded components, making our electrical products not only functional but also visually attractive.

4. Functionality Enhancement with Injection Molded Components

Injection molded components play a vital role in enhancing the functionality of electrical products. In the production of household appliances, custom – molded components can be designed to improve user experience. For example, in microwave ovens, injection molded turntable supports are engineered to ensure smooth rotation and even heating of food. In industrial electrical equipment, injection molded parts can be used to create durable and reliable enclosures that protect internal components from dust, moisture, and mechanical damage.

For electrical devices with advanced features, such as touch – screen interfaces or wireless charging capabilities, injection molded components can be precisely engineered to house and support these functions. The tight tolerances achievable through injection molding ensure that all components fit together seamlessly, enabling the smooth operation of complex electrical systems. By integrating these functional elements into injection molded components, we can create electrical products that offer enhanced performance and usability.

5. Environmental Sustainability of Injection Molded Components

As environmental concerns gain increasing importance, injection molded components can contribute significantly to the sustainability of the electrical product industry. Many of the plastics used in injection molding are recyclable, such as polycarbonate, ABS, and polyethylene. By promoting the recycling of these materials, we can reduce the demand for virgin plastics and minimize environmental waste.

In addition, injection molding allows for material optimization. Advanced simulation tools can be used during the mold design phase to precisely calculate the amount of plastic required for each component, minimizing material waste. Some manufacturers are also exploring the use of bio – based plastics in injection molding, which are derived from renewable resources and have a lower environmental impact. By adopting these sustainable practices in the production of injection molded components, we can make the manufacturing of electrical products more environmentally friendly while still meeting the market’s demand for high – quality, innovative products.