In the rapidly evolving landscape of electrical products, multi-shot injection molding has emerged as a revolutionary manufacturing technique, enabling us to craft highly sophisticated, reliable, and efficient solutions. This advanced process allows us to combine diverse materials with distinct properties in a single molding cycle, addressing the complex and multifaceted requirements of the electrical industry. From enhancing product performance and durability to enabling innovative designs and sustainable production, multi-shot injection molding is propelling us towards new heights of excellence in electrical product manufacturing.

1. Unveiling the Intricate Process of Multi-Shot Injection Molding in Electrical Product Manufacturing

The application of multi-shot injection molding in electrical products commences with the sequential injection of two or more materials into the same mold cavity. We typically start by injecting the primary material, which serves as the structural backbone of the electrical component, such as a robust thermoplastic for the outer casing of a power adapter. Once the primary material has partially solidified, we introduce the secondary material, which could be a specialized electrical insulator, a conductive compound for signal transmission, or a material with superior mechanical strength.

Precision control over various parameters is paramount in this process. Advanced molding machines equipped with state-of-the-art sensors and control systems enable us to manage factors like temperature, pressure, and injection speed with utmost accuracy. For example, maintaining the injection temperature within a narrow range of ±2°C is crucial when working with heat-sensitive insulating materials, as even a slight deviation can compromise the bond strength between materials by up to 15%. This meticulous control ensures that each component we produce adheres to the highest quality standards, guaranteeing consistent performance and reliability in electrical products.

2. Elevating Electrical Performance with Multi-Shot Injection Molding

One of the most significant advantages of multi-shot injection molding for us in the electrical product domain lies in its ability to enhance electrical performance. We can integrate high-performance insulating materials directly into the design of electrical enclosures, connectors, and switches. For instance, in the production of electrical outlets, by injecting a secondary layer of flame-retardant and electrically insulating polymer over the base structural material, we create a robust barrier that effectively prevents electrical leakage and reduces the risk of short circuits.

In the case of high-voltage electrical components, multi-shot molding allows us to incorporate materials with excellent dielectric properties. A study on high-voltage cable connectors showed that components produced using multi-shot injection molding with specialized dielectric materials could withstand voltage surges up to 30% higher than those made with traditional manufacturing methods. This not only improves the safety and reliability of electrical products but also extends their service life, reducing the need for frequent replacements.

3. Revolutionizing Structural Design through Multi-Shot Injection Molding

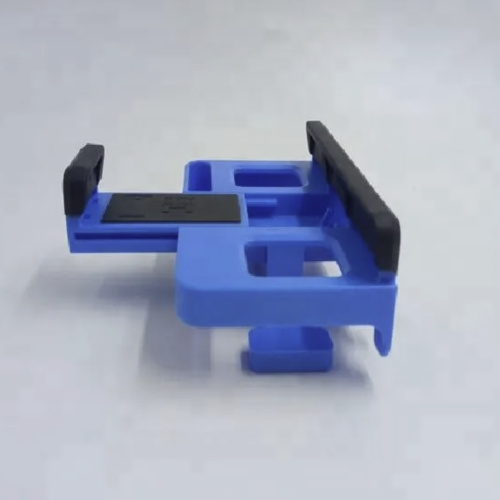

Multi-shot injection molding empowers us to reimagine the structural design of electrical products, enabling us to create more compact, lightweight, and integrated solutions. Instead of relying on multiple parts assembled together, we can mold complex, multi-functional components in a single operation. For example, in the development of smart home devices, we can integrate snap-fit features, mounting brackets, and electrical insulation layers into the housing of a Wi-Fi router, streamlining the manufacturing process and reducing the risk of component failure due to loose connections.

This technology also offers us the flexibility to experiment with innovative geometries and shapes. In the design of portable electronic devices, such as wireless earbuds, multi-shot molding allows us to create sleek, ergonomic casings that not only enhance the aesthetic appeal but also improve the user experience. By optimizing the structural design through multi-shot injection molding, we can achieve a balance between functionality, durability, and visual appeal in electrical products.

4. Expanding Functional Capabilities with Multi-Shot Injection Molding

Multi-shot injection molding opens up new possibilities for us to expand the functional capabilities of electrical products. We can combine materials with different properties to create components with enhanced functionality. For example, in the manufacturing of sensors, we can use multi-shot molding to integrate a conductive sensing element with a protective, moisture-resistant outer layer. This ensures accurate sensing while safeguarding the delicate internal components from environmental factors such as humidity and dust.

In the case of electrical switches, we can inject a soft-touch material for the actuator, providing a comfortable and tactile user experience, while the body of the switch is made from a more rigid, durable material for structural integrity. Additionally, multi-shot molding enables us to incorporate features like anti-slip textures, shock absorption, and electromagnetic shielding into electrical products, enhancing their overall performance and usability.

5. Achieving Cost Efficiency and Sustainability with Multi-Shot Injection Molding

From a business and environmental perspective, multi-shot injection molding offers us significant cost efficiency and sustainability benefits. Although the initial investment in multi-shot molding equipment is relatively high, the long-term savings are substantial. By reducing the number of parts and assembly steps, we can lower labor costs by approximately 20% and minimize the potential for errors during assembly. The streamlined production process also allows for faster production cycles, enabling us to meet high-volume demand more efficiently.

In terms of sustainability, multi-shot injection molding allows us to use recycled materials and bio-based polymers in the manufacturing process. We can design electrical products that are easier to disassemble and recycle at the end of their life cycle, minimizing the environmental impact. For example, by using recycled plastics for the outer casing of electrical appliances and combining them with new, high-performance materials for critical components through multi-shot molding, we can reduce our reliance on virgin materials and contribute to a more circular economy.