In the ever – evolving landscape of hardware tools, injection molded components have emerged as essential elements, revolutionizing the way we design, manufacture, and deliver high – performance tools. These precisely crafted components, produced through advanced injection molding techniques, play a pivotal role in enhancing the functionality, durability, and cost – effectiveness of a wide range of hardware tools, from hand tools to power – driven equipment. As we strive to meet the diverse needs of professionals, DIY enthusiasts, and industries, injection molded components empower us to create innovative tools that combine reliability, efficiency, and user – friendliness.

1. Cost – effective Production with Injection Molded Components

Cost – effectiveness is a crucial factor in the competitive hardware tool market, and injection molded components offer significant advantages. Once the mold is developed, mass production of injection molded components allows us to achieve economies of scale. For example, when manufacturing plastic handles for hammers, producing tens of thousands of units through injection molding can reduce the per – unit cost by up to 40% compared to traditional manufacturing methods. The initial investment in mold creation, which may vary based on complexity, can be recouped within a short period as production volumes increase.

Injection molded components also enable the integration of multiple functions into a single part. In the production of pliers, a custom – molded handle can combine ergonomic design, non – slip texture, and structural support. This streamlines the production process, eliminating the need for additional assembly steps and reducing labor costs. By leveraging injection molded components, we can optimize production efficiency and offer high – quality hardware tools at competitive prices, making them accessible to a broader market.

2. Quality Assurance of Injection Molded Components

Maintaining consistent quality is of utmost importance in the hardware tool industry, and injection molded components are manufactured with precision to meet strict standards. Advanced injection molding machines are equipped with sophisticated control systems that monitor and regulate parameters such as temperature, pressure, and injection speed with high accuracy. This ensures that each injection molded component has uniform dimensions, consistent wall thickness, and excellent structural integrity.

For instance, in the production of electrical outlet covers for tool storage boxes, injection molding guarantees a precise fit, flame – retardant properties, and a smooth surface finish. Automated inspection systems, utilizing machine vision and sensor technologies, can detect any defects, such as warping, voids, or dimensional inaccuracies, in real – time. Defective components are immediately removed from the production line, ensuring that only top – quality injection molded parts are used in the final assembly of hardware tools. This strict quality control process not only enhances the reliability and lifespan of our products but also helps us build trust with users.

3. Design Flexibility of Injection Molded Components

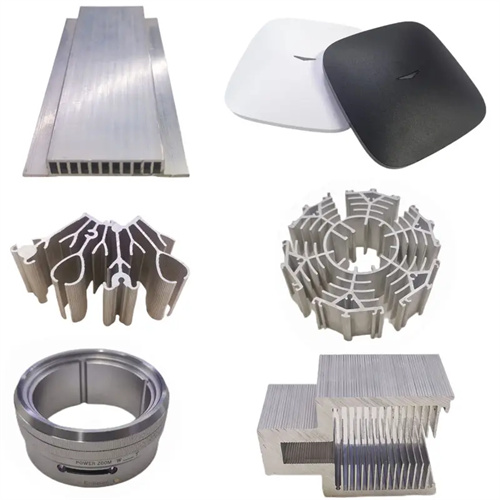

Injection molded components offer remarkable design flexibility, enabling us to create hardware tools with unique and innovative designs. With the aid of computer – aided design (CAD) and computer – aided manufacturing (CAM) technologies, we can develop complex geometries, ergonomic shapes, and intricate details. In the design of garden shears, injection molded handles can be shaped to fit comfortably in the hand, with textured surfaces for a secure grip and built – in shock – absorbing features.

We also have a wide range of materials and finishes to choose from. High – impact resistant plastics can be used for tool housings to ensure durability, while materials with anti – static properties are suitable for components in electrical tools. Surface treatments such as texture embossing, color – matching, and applying a matte or glossy finish can be used to enhance the aesthetic appeal of injection molded components, making our hardware tools not only functional but also visually appealing.

4. Functionality Enhancement with Injection Molded Components

Injection molded components play a vital role in enhancing the functionality of hardware tools. In the production of wrenches, custom – molded jaws can be designed with specific shapes and textures to provide a better grip on different types of nuts and bolts. The precise tolerances achieved through injection molding ensure that the jaws fit snugly, allowing for more efficient torque application and reducing the risk of slippage.

For power tools, such as drills and saws, injection molded components can house electrical components, provide structural support, and incorporate cooling channels to prevent overheating. These components are engineered with precision to ensure the smooth operation of the tools and enhance their performance. By integrating these functional elements into injection molded components, we can create hardware tools that are more efficient, reliable, and user – friendly.

5. Environmental Sustainability of Injection Molded Components

As environmental concerns gain increasing importance, the hardware tool industry is focusing on sustainability, and injection molded components can contribute significantly to this goal. Many of the plastics used in injection molding are recyclable, such as polypropylene and polyethylene. By promoting the recycling of these materials, we can reduce the demand for virgin plastics and minimize environmental waste.

In addition, injection molding allows for material optimization. Advanced simulation tools can be used during the mold design phase to precisely calculate the amount of plastic required for each component, minimizing material waste. Some manufacturers are also exploring the use of bio – based plastics in injection molding, which are derived from renewable resources and have a lower environmental impact. By adopting these sustainable practices in the production of injection molded components, we can make the manufacturing of hardware tools more environmentally friendly while still meeting the market’s demand for high – quality products.