In the rapidly evolving landscape of LED lighting, high – volume injection molded parts have emerged as a driving force behind efficient production, cost – effectiveness, and innovative design. These precisely manufactured components, produced in large quantities, play a pivotal role in shaping the functionality, durability, and aesthetic appeal of LED lighting products. From residential lighting fixtures to large – scale commercial and industrial applications, high – volume injection molding technology empowers us to meet the growing demand for energy – efficient and high – quality LED lighting solutions while maintaining strict quality control standards.

1. Cost – Efficiency Gained through High – Volume Injection Molded Parts

Cost – efficiency is a crucial factor in the highly competitive LED lighting market, and high – volume injection molded parts offer significant advantages. Once the mold is developed, the mass production of identical components allows us to achieve economies of scale. For example, when manufacturing LED bulb housings, producing hundreds of thousands of units through high – volume injection molding reduces the per – unit cost significantly compared to small – batch production. The initial investment in mold development is offset by the lower production costs associated with large – scale manufacturing. Additionally, high – volume injection molding enables the integration of multiple functions into a single part. In LED downlights, a custom – molded plastic frame can combine structural support, heat dissipation features, and electrical component housing, streamlining the production process and cutting down on assembly costs. This cost – effectiveness allows us to offer LED lighting products at competitive prices, making energy – efficient lighting more accessible to consumers.

2. Consistent Quality Assurance of High – Volume Injection Molded Parts

Maintaining consistent quality is essential in LED lighting production, and high – volume injection molded parts excel in this aspect. Advanced injection molding machines are equipped with precise control systems that ensure each part is produced with the same high level of accuracy. For instance, in the production of LED strip light diffusers, high – volume injection molding guarantees uniform light – transmitting properties across all units. The tight tolerances achieved through this process prevent variations in thickness or surface finish, which could affect the lighting performance. Rigorous quality control measures are integrated into the high – volume production line. Automated inspection systems use machine vision technology to detect any defects, such as warping, voids, or dimensional inaccuracies, in the molded parts. By promptly removing defective products, we can ensure that all LED lighting components meet the strictest industry standards, providing reliable and high – quality products to customers.

3. Design Flexibility Enabled by High – Volume Injection Molded Parts

High – volume injection molding offers remarkable design flexibility for LED lighting products. With the help of computer – aided design (CAD) and computer – aided manufacturing (CAM) technologies, we can create complex geometries and intricate details that enhance both the functionality and aesthetics of the fixtures. In modern LED pendant lights, high – volume injection molded parts can be shaped into unique, organic forms that serve as both the structural framework and the decorative element. These parts can be molded with built – in grooves for cable management, ventilation holes for heat dissipation, or even integrated light – guiding structures. Moreover, we have the option to choose from a wide range of materials and finishes. For example, using high – impact polymers with a matte finish for LED street light housings not only provides durability but also reduces glare, improving the visual comfort of pedestrians and drivers. This design flexibility allows us to develop LED lighting products that stand out in the market while meeting the specific requirements of different applications.

4. Heat Dissipation Enhancement with High – Volume Injection Molded Parts

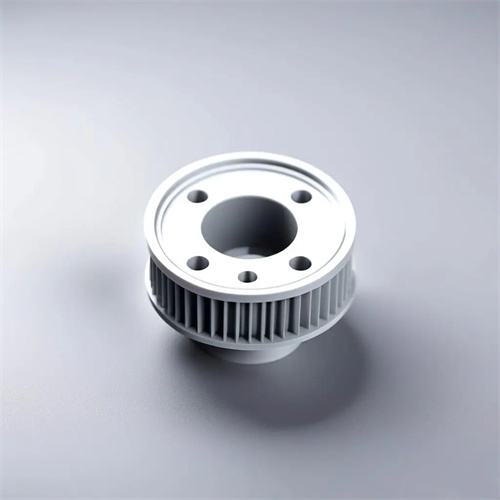

Efficient heat dissipation is critical for the performance and lifespan of LED lighting products, and high – volume injection molded parts can contribute significantly to this aspect. Specialized heat – conductive plastics and innovative design techniques are employed to create components that effectively transfer heat away from the LED chips. In LED floodlights, high – volume injection molded heat sinks with carefully designed fin structures can increase the surface area for heat dissipation. These fins are precisely molded to optimize air flow around the LED modules, ensuring that the temperature remains within the optimal operating range. By improving heat dissipation, we can prevent overheating, which can lead to reduced light output, color degradation, and premature failure of the LEDs. This not only extends the lifespan of the LED lighting products but also maintains their consistent performance over time.

5. Environmental Sustainability of High – Volume Injection Molded Parts

In an era of growing environmental awareness, the use of high – volume injection molded parts in LED lighting can contribute to more sustainable practices. Many of the plastics used in injection molding are recyclable, such as polycarbonate and polypropylene. By promoting the recycling of these materials, we can reduce the demand for virgin plastics and minimize environmental waste. Additionally, high – volume production allows for material optimization. Advanced simulation tools can be used during the mold design phase to minimize material waste by precisely calculating the amount of plastic required for each part. Some manufacturers are also exploring the use of bio – based plastics in high – volume injection molding, which are derived from renewable resources and have a lower environmental impact. By adopting these sustainable practices, we can make LED lighting production more environmentally friendly while still meeting the market’s demand for high – quality products.