In the ever – changing and competitive landscape of the packaging industry, injection molded plastics have emerged as a driving force behind innovation, functionality, and sustainability. These precisely engineered plastic components, produced through advanced injection molding techniques, play a crucial role in every aspect of packaging, from safeguarding products during transit to enhancing the consumer experience at the point of sale. As we strive to meet the evolving demands of various industries and consumers, injection molded plastics empower us to create packaging solutions that are not only practical and cost – effective but also environmentally responsible.

1. Material Innovation with Injection Molded Plastics

Injection molded plastics have opened the door to a wide range of material innovations in the packaging industry. We now have the ability to select from an extensive array of polymers with specific properties tailored to different packaging needs. For instance, high – barrier plastics, such as ethylene – vinyl alcohol copolymers (EVOH), can be injection molded into food packaging containers. These containers provide excellent protection against oxygen, moisture, and other external factors, significantly extending the shelf life of perishable goods like fresh produce and dairy products.

In the pharmaceutical industry, we utilize biocompatible plastics through injection molding for blister packs and pill bottles. Materials like polypropylene (PP) are not only safe for direct contact with medications but also offer good chemical resistance, ensuring the integrity of the drugs throughout their storage and distribution. Moreover, the development of anti – static plastics has been a game – changer for packaging electronic components. Injection molded anti – static trays and cases prevent electrostatic discharge, protecting sensitive electronics from damage during handling and transportation.

2. Customization and Branding with Injection Molded Plastics

One of the key advantages of injection molded plastics in the packaging industry is the high level of customization they offer. With the help of computer – aided design (CAD) and computer – aided manufacturing (CAM) technologies, we can create unique packaging shapes, sizes, and designs that perfectly match the brand identity of our clients. For example, luxury cosmetic brands often opt for injection molded plastic compacts and bottles with intricate patterns, elegant curves, and the brand’s logo embossed or engraved directly onto the surface.

We can also customize the color, texture, and finish of injection molded plastics. Matte finishes can give a sophisticated look to premium products, while glossy finishes can make packaging more eye – catching on the shelves. In addition, we can apply special effects like metallic coatings or pearlescent pigments to injection molded plastic packaging, adding a touch of luxury and making the products stand out among competitors. This level of customization not only enhances the visual appeal of the packaging but also helps in building a strong brand image.

3. Structural Integrity and Protection with Injection Molded Plastics

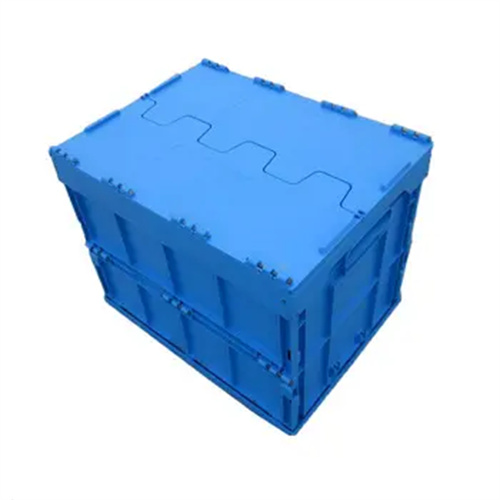

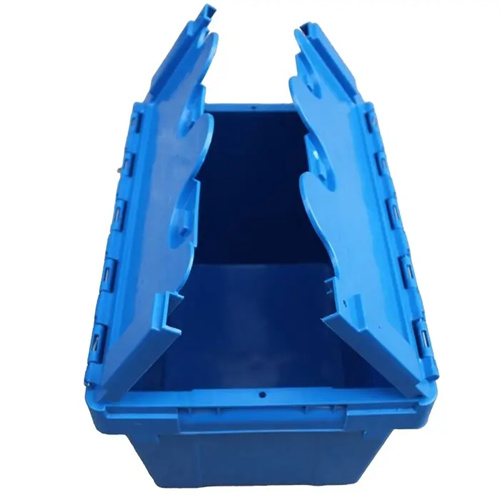

Injection molded plastics provide exceptional structural integrity, making them ideal for protecting products during storage, transportation, and handling. In the automotive parts packaging sector, we use injection molded plastic crates and containers with reinforced corners and ribbed structures. These designs can withstand heavy loads, impacts, and vibrations, ensuring that delicate automotive components such as engines, transmissions, and electronics arrive at their destination in perfect condition.

For fragile items like glassware and ceramics, injection molded plastic inserts and dividers can be customized to fit the shape of the products precisely. These inserts provide cushioning and prevent the items from shifting or colliding with each other, reducing the risk of breakage. In the case of large – scale industrial products, injection molded plastic shipping cases can be designed to be stackable, further optimizing storage and transportation space while maintaining the protection of the contents.

4. Smart Packaging Solutions with Injection Molded Plastics

The rise of smart packaging has been significantly enabled by injection molded plastics. We can integrate various smart features into injection molded plastic packaging, such as RFID (Radio – Frequency Identification) tags, sensors, and indicators. For example, in the food and beverage industry, injection molded plastic caps with integrated sensors can monitor the freshness of the product by detecting changes in temperature, humidity, or gas levels inside the container. This information can be transmitted wirelessly to consumers or supply chain managers, ensuring product quality and safety.

Injection molded plastic packaging for consumer electronics can also incorporate RFID tags, which enable easy tracking and inventory management throughout the supply chain. Additionally, time – temperature indicators molded into plastic packaging can show whether a temperature – sensitive product, like vaccines or certain medications, has been stored and transported within the appropriate temperature range. These smart packaging solutions not only enhance the functionality of the packaging but also provide valuable data for various stakeholders in the industry.

5. Environmental Sustainability Initiatives with Injection Molded Plastics

As environmental concerns become more prominent, the packaging industry is actively seeking sustainable solutions, and injection molded plastics are no exception. We are increasingly using recyclable plastics in injection molding, such as polyethylene terephthalate (PET) and high – density polyethylene (HDPE). These materials can be recycled multiple times, reducing the demand for virgin plastics and minimizing environmental waste.

In addition, we are exploring the use of bio – based plastics in injection molding. Materials like polylactic acid (PLA), derived from renewable resources such as corn starch or sugarcane, offer a more environmentally friendly alternative to traditional petroleum – based plastics. Although there are still challenges in terms of performance and cost, continuous research and development are making bio – based plastics more viable for various packaging applications. Furthermore, through optimized mold design and advanced manufacturing techniques, we can minimize material waste during the production of injection molded plastics, contributing to a more sustainable packaging industry.