In the dynamic and competitive sports goods industry, injection molded plastics have emerged as a cornerstone material, enabling us to produce equipment and accessories that combine performance, durability, and comfort. By leveraging the versatility of various plastic polymers and the precision of injection molding processes, we can create products that meet the diverse needs of athletes across different sports, from enhancing athletic performance to ensuring safety during use. Injection molded plastics are not only driving innovation in sports gear design but also playing a crucial role in improving the overall quality and functionality of sports goods.

1. The Multifaceted Properties of Injection Molded Plastics for Sports Goods

When we embark on the production of sports goods, the choice of injection molded plastics is rooted in their wide – ranging and adaptable properties. Plastics offer excellent impact resistance, which is essential for sports equipment that endures frequent collisions, falls, and intense physical interactions. Materials like polycarbonate and ABS can withstand high – force impacts without cracking or breaking easily, making them ideal for protective gear such as helmets, shin guards, and knee pads.

Lightweight yet strong, injection molded plastics also contribute significantly to sports performance. In sports where every gram matters, such as cycling, running, and track and field, plastics like nylon and polypropylene are used to create lightweight components without sacrificing strength. This allows athletes to move more freely and perform at their best. Additionally, plastics can be engineered to have specific surface textures and frictional properties. For example, the handles of sports equipment can be made with a textured plastic surface to provide a secure grip, even when hands are sweaty. Their chemical resistance to substances like sweat, water, and sports – specific cleaning agents ensures that the sports goods maintain their integrity and appearance over time.

2. Injection Molded Plastics in Sports Protective Gear

Injection molded plastics play a vital role in the manufacturing of sports protective gear. Helmets, a critical piece of safety equipment in many sports, often rely on injection molded plastics for their shells and liners. High – impact – resistant plastics form the outer shell, providing a tough barrier against impacts from balls, other players, or hard surfaces. The inner liners, made from softer, more cushioned plastics, help absorb and distribute the force of an impact, reducing the risk of head injuries.

Shin guards and knee pads also benefit from injection molded plastics. The hard outer shells, molded from durable plastics, protect the joints and bones from direct blows, while the inner layers, made from flexible and shock – absorbing plastics, conform to the body’s contours for a comfortable fit. In contact sports like football, hockey, and soccer, these protective gears made with injection molded plastics are essential for safeguarding athletes and allowing them to compete with confidence.

3. Injection Molded Plastics for Sports Equipment Frames

For sports equipment frames, such as those of tennis rackets, badminton rackets, and bicycles, injection molded plastics offer a reliable and cost – effective solution. By combining plastics with reinforcing materials like carbon fiber or glass fiber, we can create frames that are lightweight yet possess excellent strength and stiffness. In tennis and badminton rackets, injection molded plastic frames can be designed with aerodynamic shapes and precisely placed holes to reduce air resistance and increase swing speed.

The precision of injection molding allows for the creation of complex geometries that optimize the balance and performance of the rackets. For bicycles, injection molded plastic components in the frame contribute to weight reduction, making the bike more agile and responsive on the road or trail. The durability of these plastics ensures that the frames can withstand the rigors of regular use, including vibrations, impacts, and exposure to different weather conditions.

4. Precision and Cost – Efficiency of Injection Molded Plastics in Sports Goods Production

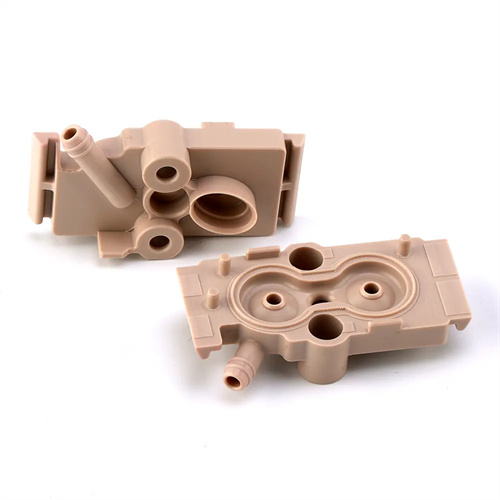

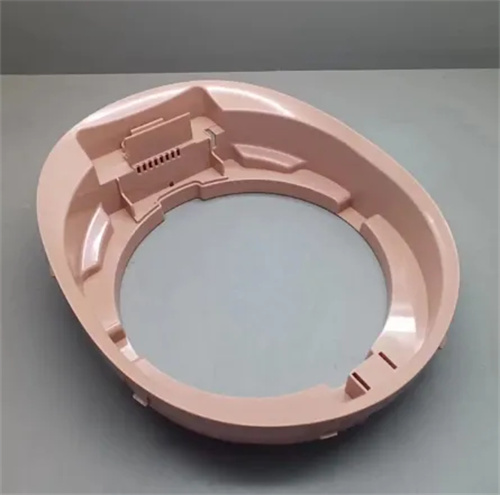

Precision is at the core of our injection molding processes for sports goods. Advanced injection molding machines, equipped with sophisticated computer – controlled systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing small and intricate components, like the tiny buttons on sports watches, the connectors on fitness trackers, or the clips on sports bags, we can fine – tune the injection process to achieve extremely tight tolerances. This precision ensures a perfect fit and seamless operation of the sports goods.

Cost – efficiency is another significant advantage of using injection molded plastics in sports goods production. The relatively low cost of plastic raw materials, combined with the high – volume production capabilities of injection molding, enables us to produce components at a competitive cost per unit. When manufacturing 10,000 injection – molded bicycle handlebar grips in a batch, for instance, the cost per piece can be significantly reduced through economies of scale. The automated nature of the injection molding process also cuts down on labor costs, as computer – controlled machines handle most of the production tasks, minimizing the risk of human – error – related defects.

5. Future Prospects of Injection Molded Plastics in the Sports Goods Industry

As we look to the future, we are excited about the potential of injection molded plastics in the sports goods industry. With the continuous advancement of sports technology and the increasing demand for high – performance, sustainable sports products, we anticipate the development of new plastic materials with enhanced properties. Researchers may focus on creating plastics with even better impact absorption, lighter weights, and improved environmental friendliness.

The integration of smart features into sports equipment will also present new opportunities for injection molded plastics. We expect to embed sensors, microcontrollers, and wireless communication modules into plastic components, enabling features such as real – time performance tracking, injury prevention, and personalized training programs. Additionally, as sustainability becomes an even more critical issue, efforts will be made to develop more eco – friendly plastic formulations, such as bio – based plastics, to reduce the environmental impact of sports goods production. These future developments will undoubtedly expand the applications and influence of injection molded plastics, driving the continued innovation and growth of the sports goods industry.