In the competitive and innovative sports goods industry, multi – shot injection molding has emerged as a transformative technology, enabling us to produce sports equipment and accessories that seamlessly integrate multiple materials, functions, and ergonomic designs. By leveraging the precision and flexibility of this advanced process, we can create high – performance products that meet the diverse needs of athletes, from enhancing protection and comfort to optimizing performance during intense sports activities. Multi – shot injection molding is not only revolutionizing the manufacturing of sports goods but also setting new standards for quality and innovation in the industry.

1. The Distinctive Features of Multi – Shot Injection Molding for Sports Goods

When we undertake the production of sports goods, the adoption of multi – shot injection molding is driven by its unique and advantageous features. This sophisticated process allows us to inject two or more different materials, such as rigid plastics, flexible elastomers, and even functional additives, into a single mold cavity in multiple sequential shots. With the aid of advanced multi – shot injection molding machines equipped with precise control systems, we can accurately regulate the injection parameters for each material, ensuring perfect integration and optimal performance of the final product.

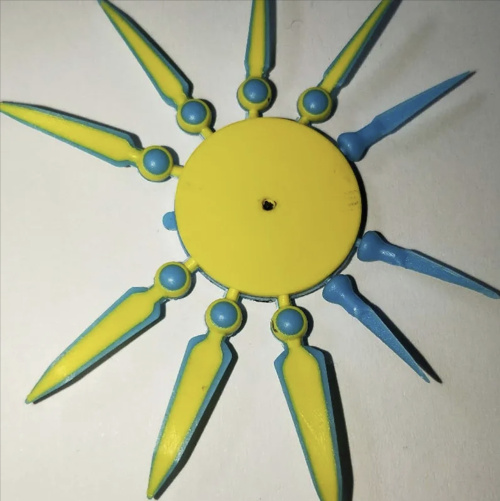

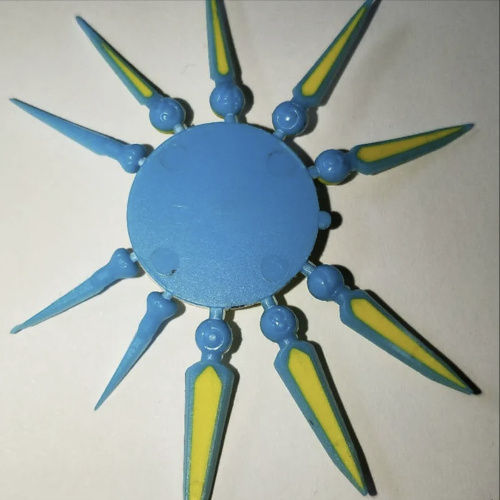

One of the key benefits is the ability to combine materials with complementary properties. For example, we can integrate a hard, impact – resistant plastic for structural support with a soft, cushioned elastomer for comfort and shock absorption in a single sports equipment component. This eliminates the need for complex assembly processes that join separate parts, reducing production time and potential failure points. Additionally, multi – shot injection molding offers unparalleled design freedom, enabling us to create intricate color patterns, textures, and customized shapes that enhance the visual appeal and brand identity of sports goods.

2. Multi – Shot Injection Molding in High – Performance Sports Footwear

Multi – shot injection molding plays a crucial role in the production of high – performance sports footwear. We can use this technology to create shoe soles that combine multiple materials for enhanced functionality. For instance, by injecting a durable, high – traction rubber as the outer layer of the sole, we ensure excellent grip on various surfaces, while a softer, energy – absorbing foam material can be added in a subsequent shot for cushioning and shock absorption. This combination not only improves the athlete’s performance but also reduces the risk of injuries caused by impact.

In addition to the sole, multi – shot injection molding can be applied to other parts of the shoe, such as the upper. We can integrate breathable mesh materials with supportive thermoplastic overlays in a single molding process, creating a shoe that offers both ventilation and stability. The ability to customize the color and pattern of each material layer during the multi – shot process also allows for the creation of unique and eye – catching shoe designs that appeal to athletes and consumers alike.

3. Multi – Shot Injection Molding for Protective Sports Gear

Protective sports gear, such as helmets, knee pads, and elbow pads, greatly benefits from multi – shot injection molding. When manufacturing helmets, we can use this technology to combine a hard outer shell made of high – impact – resistant plastic with an inner layer of shock – absorbing foam or padding. The precise control over the injection process ensures a perfect fit between the two layers, providing maximum protection against impacts while maintaining a lightweight design.

For knee and elbow pads, multi – shot injection molding allows us to create components that combine a rigid outer structure for protection with a soft, skin – friendly inner layer for comfort. We can also integrate features like adjustable straps or ventilation channels directly into the molding process, enhancing the functionality and usability of the protective gear. The ability to use different colors and textures for each material layer also makes it easier to distinguish between different types of protective gear and adds a touch of personalization.

4. Efficiency and Quality Enhancement of Multi – Shot Injection Molding in Sports Goods Production

Although multi – shot injection molding may seem complex and costly at first glance, it offers significant efficiency and quality benefits in sports goods production. The elimination of multiple assembly steps reduces production time and labor costs, allowing us to bring products to market more quickly. By producing components with integrated functions and designs in a single molding process, we also minimize the risk of errors and inconsistencies that can occur during assembly.

In terms of quality, multi – shot injection – molded sports goods outperform traditional products. The seamless integration of different materials results in components with superior mechanical properties, such as increased strength, flexibility, and durability. For example, a multi – shot – molded tennis racket frame that combines a high – modulus carbon – fiber – reinforced plastic with a vibration – dampening elastomer can offer better control, power, and comfort to the player. The consistent quality and performance of multi – shot injection – molded sports goods also enhance customer satisfaction and brand reputation.

5. Future Prospects of Multi – Shot Injection Molding in the Sports Goods Industry

As we look to the future, we are excited about the potential of multi – shot injection molding in the sports goods industry. With the continuous advancement of sports technology and the growing demand for innovative, high – performance products, we anticipate further developments in this technology. New materials, such as advanced composites and smart polymers, will likely be integrated into multi – shot injection molding processes, enabling the creation of sports goods with enhanced properties like self – adjustment, energy harvesting, and real – time performance monitoring.

The increasing focus on sustainability will also drive the development of eco – friendly multi – shot injection molding solutions. We expect to see more use of recycled materials and bio – based polymers in sports goods production, reducing the environmental impact of manufacturing while maintaining product quality. Additionally, advancements in digital design and simulation technologies will allow us to optimize the multi – shot injection molding process more effectively, creating more customized and personalized sports products that meet the unique needs of individual athletes.