Streamlined Design for Rapid Custom Injection Molded Parts

We’ve revolutionized the design phase to accelerate the production of custom injection molded parts, ensuring your project stays on track for our 15-day turnaround promise. Our design team uses cloud-based collaboration tools to work directly with your engineers, reviewing 3D models in real time and providing instant feedback on moldability. We employ AI-powered design for manufacturing (DFM) software that flags potential issues—like undercuts or uneven wall thickness—within hours, not days, allowing for quick revisions. For standard part geometries, we offer a library of pre-approved templates that reduce design time by up to 40%. We also prioritize material selection early, recommending readily available resins that meet your specifications, avoiding delays caused by sourcing specialty materials. By integrating these streamlined processes, we ensure that the design phase—typically a bottleneck—takes just 1 to 2 days, setting the foundation for fast delivery of your custom injection molded parts.

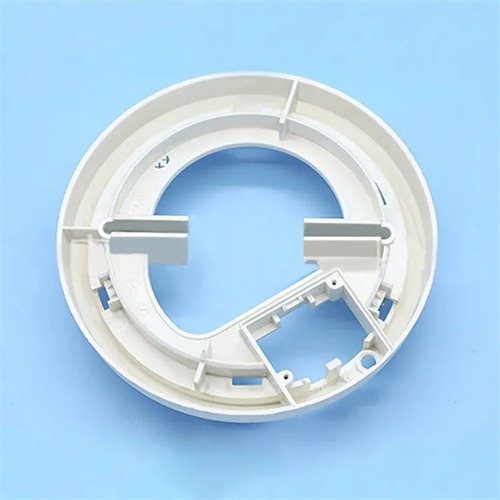

Rapid Tooling for Fast-Turnaround Custom Injection Molded Parts

Our rapid tooling capabilities are the cornerstone of our ability to deliver custom injection molded parts in 15 days or less, combining speed without sacrificing precision. We use high-grade aluminum and pre-hardened steel for mold construction, which can be machined 50% faster than traditional tool steel while maintaining tolerances of ±0.001 inches. Our tooling department operates 24/7, with automated CNC machines that run unattended, cutting mold components around the clock. We’ve standardized mold bases and modular components, allowing us to assemble tools in as little as 3 to 5 days for simple designs. For more complex parts with undercuts or threads, we use pre-fabricated sliding mechanisms that integrate quickly into the mold structure. Each rapid tool undergoes a 24-hour test run to verify performance, ensuring no delays during production. This approach means even custom molds for intricate parts are ready for production within a week, keeping your project on schedule for fast delivery.

Expedited Production Scheduling for Custom Injection Molded Parts

We’ve reimagined production scheduling to prioritize speed, ensuring that once tooling is complete, custom injection molded parts move through manufacturing without delays. Our facility operates three 8-hour shifts daily, with dedicated production cells reserved for fast-turnaround projects. We use a dynamic scheduling system that allocates machines based on part size and complexity, ensuring your job starts within 24 hours of tooling approval. For small to medium runs (1,000 to 100,000 parts), we use single-cavity molds with quick-change setups that reduce machine downtime to less than 2 hours. Our automated production lines feature robotics for part handling and inline inspection, eliminating bottlenecks caused by manual processes. We also maintain a stock of common resins—like ABS, PP, and PC—so material is available immediately when production begins. By optimizing every step, we can complete production of most custom injection molded parts in 3 to 5 days, bringing us closer to the 15-day goal.

Agile Quality Control for Fast-Turnaround Custom Injection Molded Parts

We’ve designed our quality control processes to be both rigorous and efficient, ensuring custom injection molded parts meet your standards without slowing down delivery. Instead of batch inspections, we use real-time monitoring with vision systems and sensors that check dimensions, surface finish, and material properties as parts are produced. This inline inspection flags issues immediately, allowing our team to adjust parameters on the fly, reducing scrap and rework. We’ve also developed a library of inspection templates for common part geometries, cutting setup time for quality checks by 60%. For critical dimensions, we use automated CMM (Coordinate Measuring Machine) scans that generate reports in minutes, not hours. Our quality team works alongside production staff in dedicated fast-turnaround cells, ensuring constant communication and rapid resolution of any concerns. This agile approach means quality control adds just 1 to 2 days to the process, ensuring your custom injection molded parts are both fast and flawless.

Express Material Sourcing for Custom Injection Molded Parts

Material sourcing is a key component of our fast-turnaround promise, with systems in place to ensure the right resins are available when needed for custom injection molded parts. We maintain a strategic inventory of 20+ common engineering plastics, including flame-retardant, food-grade, and UV-stabilized formulations, all certified and ready for immediate use. For specialty materials, we’ve partnered with 10+ global suppliers who offer 48-hour expedited shipping to our facility. Our material scientists pre-test alternative resins for compatibility, so if your first-choice material is unavailable, we can recommend a suitable substitute with similar properties, avoiding delays. We also use just-in-time (JIT) delivery for high-volume fast-turnaround projects, coordinating with suppliers to deliver materials exactly when production starts. By combining inventory management with strong supplier relationships, we ensure material sourcing adds no more than 2 to 3 days to the timeline, keeping your custom injection molded parts on track for 15-day delivery.

Accelerated Logistics for Fast Delivery of Custom Injection Molded Parts

The final step in our fast-turnaround process is logistics, with solutions designed to get custom injection molded parts to your door as quickly as possible. Once production and inspection are complete, we offer multiple shipping options tailored to your needs: express air freight for 1 to 3 day delivery to global destinations, or ground shipping for domestic orders that arrive in 2 to 5 days. Our logistics team works with 5+ trusted carriers who prioritize our fast-turnaround shipments, ensuring they’re loaded and dispatched within 4 hours of production completion. We also offer local pickup for clients within 100 miles of our facility, allowing same-day receipt of parts. For international orders, we handle all customs documentation in-house, with a team specializing in fast-track clearance that reduces border delays by 70%. By integrating these logistics solutions, we ensure that shipping adds just 2 to 5 days to the process, making the 15-day promise for custom injection molded parts a reality.