Design Optimization for Intricate Injection Molded Components

We thrive on turning complex design concepts into tangible injection molded components, leveraging advanced design tools to optimize even the most intricate geometries. Our engineering team uses cutting-edge CAD software paired with finite element analysis (FEA) to simulate how molten plastic flows into every nook and cranny of a mold, identifying potential issues like air traps or uneven filling before production begins. This proactive approach allows us to refine part designs—adding fillets to sharp corners, adjusting wall thicknesses, or incorporating strategic gating locations—to ensure that even components with undercuts, thin-walled sections, or internal cavities can be molded flawlessly. For example, we recently worked on a medical device component with a spiral internal channel and multiple micro-holes; by optimizing the draft angles and gate placement during the design phase, we eliminated defects that would have compromised functionality. This focus on design for manufacturability (DFM) ensures that our injection molded components not only meet the geometric specifications but also maintain structural integrity and performance.

Material Science Enabling Complex Injection Molded Components

The success of complex geometry injection molded components hinges on selecting the right materials, and we’ve curated a portfolio of advanced polymers that excel in challenging shapes. High-flow resins, such as modified PBT and PC/ABS blends, are our go-to for components with thin walls or long flow paths, as they can penetrate intricate details without excessive pressure. For parts requiring both complexity and strength—like automotive sensor housings with integrated mounting brackets—we use glass-reinforced thermoplastics that maintain rigidity even in irregular shapes. We also specialize in overmolding, where two different materials (such as a rigid substrate and a soft elastomer) are molded in a single process to create complex, multi-functional components. This technique is ideal for products like ergonomic handles with textured grips or waterproof enclosures with flexible gaskets. By matching material properties to geometric demands, we ensure that our injection molded components are not just visually complex but also engineered to perform under stress, temperature changes, and other real-world conditions.

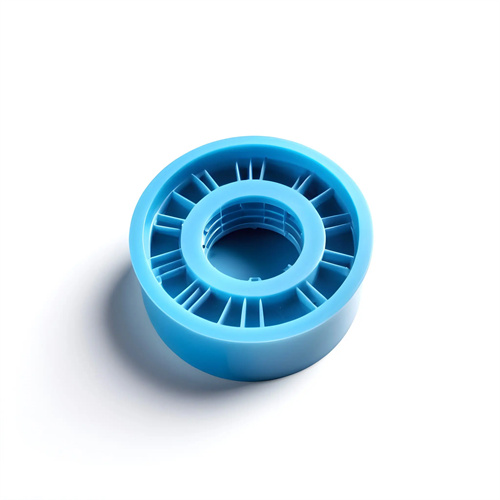

Precision Molding Technologies for Complex Injection Molded Components

Our advanced injection molding technologies are the backbone of our ability to produce complex geometry components with consistent precision. We utilize electric and hybrid molding machines with closed-loop control systems that maintain exact pressure and temperature profiles, critical for filling complex molds uniformly. For micro-molding applications—such as tiny connectors with intricate pin arrays—we employ specialized machines with clamping forces as low as 5 tons and precision injection units that can deliver material in nanogram quantities. We also invest in multi-axis robotic systems that handle post-molding operations like trimming, assembly, or inspection, ensuring that even components with hard-to-reach features are processed without damage. Another key technology is gas-assisted injection molding, where nitrogen gas is injected into the molten plastic to create hollow sections, reducing weight and eliminating sink marks in thick-walled, complex parts. These technologies, combined with our team’s expertise, allow us to push the boundaries of what’s possible, turning the most challenging geometric designs into high-quality injection molded components.

Quality Assurance for Complex Injection Molded Components

Ensuring quality in complex injection molded components requires specialized inspection techniques that can verify intricate details and tight tolerances. We’ve equipped our quality labs with advanced tools like 3D scanners and computed tomography (CT) machines, which create detailed digital models of components to compare against CAD designs. This allows us to check internal features, hidden cavities, and complex surfaces that traditional measurement tools can’t reach. For example, a CT scan of a complex gear with internal teeth can reveal misalignments or dimensional variations that would cause performance issues. We also use automated optical inspection (AOI) systems with high-resolution cameras to detect surface defects—like micro-cracks or uneven textures—on components with irregular shapes. Every complex part undergoes statistical process control (SPC), where key dimensions are measured at regular intervals during production to ensure consistency. This rigorous quality assurance process gives our clients confidence that even their most geometrically complex injection molded components meet the highest standards of accuracy and reliability.

Industry Applications Showcasing Complex Injection Molded Components

Complex injection molded components are transforming industries by enabling innovative designs that were once impossible with traditional manufacturing methods. In the aerospace sector, we produce lightweight structural brackets with complex lattice structures that reduce weight while maintaining strength, contributing to fuel efficiency in aircraft. The electronics industry relies on our intricate housing components with integrated heat sinks and cable management channels, which protect sensitive circuitry in compact devices like smartphones and drones. In the medical field, we manufacture complex surgical instruments with ergonomic grips, fluid channels, and precision locking mechanisms, all molded as single parts to minimize assembly and reduce contamination risks. The automotive industry benefits from our complex underhood components, such as intake manifolds with variable geometry, which optimize engine performance. Each of these applications demonstrates how our advanced injection molding capabilities can turn complex geometries into functional, reliable components that drive innovation across sectors.

Innovations Pushing the Boundaries of Complex Injection Molded Components

We’re constantly exploring new innovations to expand our ability to produce even more complex injection molded components. One area of focus is 3D-printed molds, which allow us to create prototype tooling for complex geometries in days rather than weeks, accelerating the design validation process. We’re also researching bio-based and recyclable polymers that can be molded into complex shapes, aligning with the growing demand for sustainable manufacturing. Another exciting development is the integration of smart materials into complex components—for example, molding shape-memory polymers into intricate structures that respond to temperature or electrical signals, enabling adaptive products like self-adjusting valves or flexible sensors. We’re also collaborating with clients on multi-material molding techniques that combine metals and plastics in complex geometries, creating components with both conductivity and structural strength. By staying at the forefront of these innovations, we’re ensuring that we can meet the evolving needs of industries requiring ever-more complex injection molded components, pushing the limits of what’s possible with injection molding technology.