Design Synergy: Merging Function and Aesthetics in Injection Molded Plastics

We excel at creating injection molded plastics where functionality and form converge, turning utilitarian components into visually striking, high-performance parts. Our design process begins with mapping functional requirements—strength, durability, or conductivity—then wrapping them in ergonomic, aesthetically pleasing shapes. For example, a smartwatch casing we developed uses glass-filled polycarbonate injection molded plastics to house electronics, with a curved, matte finish that feels comfortable on the wrist while resisting scratches. We integrate features like hidden fasteners and seamless seams, eliminating visual clutter without sacrificing structural integrity. A client in home appliances wanted a blender base that cooled motors efficiently and complemented kitchen decor; our solution combined ribbed internal structures for heat dissipation with a glossy, color-matched exterior using custom injection molded plastics. This synergy ensures injection molded plastics are not just functional but also enhance the overall user experience through thoughtful design.

Smart Materials Enabling Multi-Functional Injection Molded Plastics

Smart materials are revolutionizing injection molded plastics, allowing us to integrate multiple functions into a single part without compromising form. Conductive polymers, for instance, let us create injection molded plastics that serve as both structural components and electrical conductors—ideal for sleek, wireless charging pads where metal contacts would disrupt the design. Shape-memory plastics enable injection molded plastics that respond to temperature or pressure, such as a phone case that tightens around the device when dropped, combining protection with a slim profile. We also use thermochromic materials in consumer products, like coffee mugs with injection molded plastics that change color to indicate heat, merging functionality with playful aesthetics. A recent project for a fitness tracker used a biocompatible, flexible injection molded plastic blend that adapts to wrist movement while housing sensors, proving that smart materials let injection molded plastics do more while looking better.

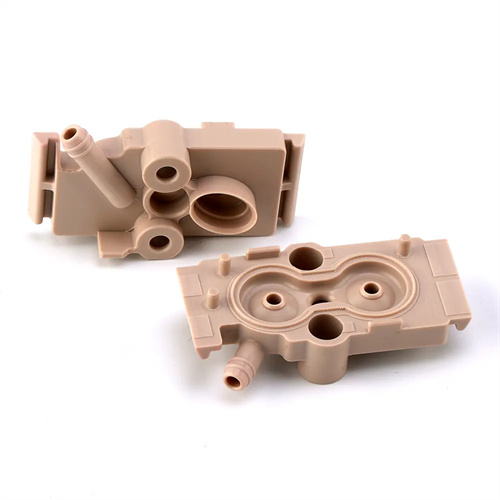

Advanced Molding Techniques for Integrated Injection Molded Plastics

Advanced molding techniques allow us to create injection molded plastics with seamlessly integrated functionality and form, eliminating the need for assembly that disrupts design. Overmolding, where we bond two materials in one cycle, lets us combine rigid structural cores with soft, grippy surfaces—our power tool handles use this to merge durability with comfort, all in a single injection molded plastic part. Insert molding integrates metal or electronic components into injection molded plastics, such as a smart thermostat housing that embeds circuit boards within a smooth, curved plastic exterior. We also use micro-molding for tiny, detailed parts like earbud nozzles, where precise channels for sound are built into injection molded plastics with a polished finish. These techniques ensure that functional elements—like vents, sensors, or fasteners—are hidden within the design, making injection molded plastics look intentional and cohesive rather than cluttered.

Industry Applications Showcasing Integrated Injection Molded Plastics

Across industries, our injection molded plastics demonstrate how integrating functionality and form drives innovation. In automotive design, we produce dashboard components with injection molded plastics that house air vents, sensors, and lighting in a unified, streamlined surface, reducing visual complexity while enhancing usability. Medical devices benefit from injection molded plastics that combine sterile, easy-to-clean exteriors with internal channels for fluid flow, like a nebulizer mask that delivers medication efficiently while fitting comfortably. Consumer electronics rely on our injection molded plastics for slim, lightweight housings that protect internal components—our laptop bezels use precision-molded plastics with integrated camera cutouts and speakers, maintaining a sleek look without sacrificing functionality. These applications prove that injection molded plastics are no longer just enclosures but integrated systems where form and function enhance each other.

User-Centric Design in Smart Injection Molded Plastics

User-centric design is at the core of our approach, ensuring injection molded plastics meet both functional needs and aesthetic preferences. We conduct usability testing to understand how people interact with products, then translate insights into injection molded plastics that feel intuitive. For example, a child’s medical device required injection molded plastics that were easy to grip for parents but safe and comfortable for children; we responded with a textured, rounded design using a soft-touch TPE overmolded onto a rigid plastic core. We also consider accessibility: our injection molded plastics for elderly care devices feature large, easy-to-press buttons with tactile feedback, merging functionality with inclusivity. A client’s smart home hub used our injection molded plastics with a matte finish that reduces glare and finger smudges, addressing both visual appeal and practical use. By putting users at the center, we ensure injection molded plastics enhance daily interactions through thoughtful integration of form and function.

Future Trends in Integrating Functionality & Form in Injection Molded Plastics

The future of smart injection molding lies in pushing the boundaries of how functionality and form integrate in injection molded plastics, with emerging technologies enabling even more seamless designs. We’re exploring 4D printing techniques, where injection molded plastics change shape over time in response to stimuli— imagine a water bottle that expands for use and collapses for storage, all in one injection molded plastic part. AI-driven design tools are helping us optimize injection molded plastics for both performance and aesthetics, generating shapes that humans might not conceive but that excel in both areas. We’re also developing self-healing injection molded plastics that repair scratches, maintaining their visual appeal while extending lifespan. A prototype for a smart mirror uses injection molded plastics with integrated light strips and touch sensors, all hidden within a frame that looks like a traditional mirror. These trends promise injection molded plastics that do more, look better, and adapt to users’ needs in ways we’re just beginning to imagine.