Technical Expertise in Multi-Shot Injection Molding for Complexity

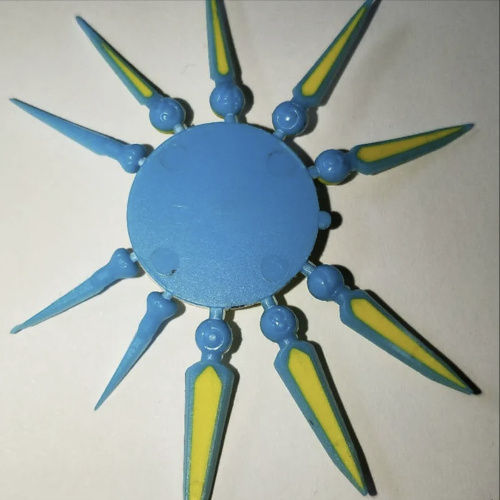

As multi-shot injection molding experts, we’ve mastered the technical nuances that enable producing complex parts in a single cycle, eliminating the need for costly assembly. Our expertise spans rotary platen, index, and vertical multi-shot machines, each configured to handle specific complexities—from micro-features to large-scale industrial components. We excel at managing material flow dynamics across shots, ensuring that dissimilar materials (like rigid plastics and elastomers) bond seamlessly without defects. For example, a 3-shot automotive sensor with embedded electronics requires precise timing between plastic, metal, and TPE injections; our process control algorithms adjust pressure and temperature in real time to prevent material mixing or voids. Our engineering team also designs molds with advanced cooling channels to manage the thermal differences between materials, a critical factor in maintaining dimensional stability. This technical mastery allows us to tackle complex geometries that would be impossible with traditional molding, all in one efficient cycle.

Part Consolidation Through Multi-Shot Injection Molding

Our multi-shot injection molding capabilities enable dramatic part consolidation, transforming assemblies with 5+ components into a single, integrated part. This reduces production steps by 60-80% while improving reliability by eliminating potential failure points like adhesives or fasteners. For instance, a consumer electronics device once requiring a housing, gasket, button, and two inserts is now produced as a 2-shot part, merging PC and TPE in one cycle. We recently consolidated a medical device assembly (consisting of a rigid frame, flexible diaphragm, and color-coded indicator) into a 3-shot component, cutting assembly labor costs by 70% and reducing defect rates from 4% to 0.5%. The key is our ability to design molds that accommodate multiple material zones without sacrificing precision—even for parts with undercuts, variable wall thicknesses, or embedded hardware. Multi-shot injection molding turns complex assemblies into streamlined parts, delivering cost and performance benefits.

Material Versatility in Multi-Shot Injection Molding

We leverage multi-shot injection molding to combine diverse materials—from high-temperature engineering resins to soft elastomers—creating complex parts with tailored properties in one cycle. Our material scientists identify compatible pairs that bond mechanically or chemically, such as PBT with silicone for heat-resistant gaskets or ABS with TPU for impact-resistant handles. We also integrate specialty materials like conductive polymers or bioresorbable plastics, enabling functionalities like EMI shielding or controlled degradation. For example, a 2-shot industrial valve uses PPS (chemical resistant) for the body and EPDM (flexible) for the seal, ensuring it withstands harsh fluids while maintaining a tight closure. We even overmold metal inserts (brass, stainless steel) with plastics, creating strong, electrically conductive connections without secondary processes. This material versatility makes multi-shot injection molding ideal for complex parts requiring conflicting properties—strength and flexibility, rigidity and softness—all in one component.

Precision Engineering for Complex Multi-Shot Injection Molding

Complex parts demand precision, and our multi-shot injection molding processes deliver tight tolerances (±0.02mm) even for intricate geometries with multiple material zones. We use advanced mold flow simulation to optimize fill sequences, ensuring each material reaches its target zones without overpacking or short shots. In-mold sensors monitor pressure, temperature, and flow rate during each shot, triggering adjustments to compensate for material variations. For example, a 3-shot micro-connector with 0.5mm pin spacing requires precise alignment between the rigid housing, conductive TPE, and metal pins—our process control system maintains positional accuracy across 100,000+ parts. We also employ diamond-polished molds to achieve smooth surface finishes on visible areas, eliminating the need for post-molding polishing. A recent project for a surgical tool with a complex curved handle (PP core, TPE overmold) maintained dimensional consistency across 50,000 units, with CMM inspections confirming 99.8% compliance. This precision ensures complex multi-shot parts perform reliably in critical applications.

Industry-Specific Complex Parts via Multi-Shot Injection Molding

We deliver industry-specific complex parts through multi-shot injection molding, addressing unique challenges across sectors in a single cycle. In automotive, our 3-shot door handles combine structural PC, decorative chrome-effect plastic, and soft TPE grips, integrating aesthetics and functionality. Medical devices benefit from 2-shot syringe plungers (PP core, LSR seal) that ensure precise drug delivery with minimal friction. Consumer goods use 2-shot kitchen tool handles (nylon core, TPE grip) for durability and comfort, while industrial equipment relies on 3-shot sensors (PBT housing, conductive insert, LSR seal) for harsh environments. Even aerospace uses our multi-shot parts—like a 2-shot bracket with a carbon-fiber-reinforced nylon core and fire-retardant overmold—meeting weight and flame-resistance requirements. A client in renewable energy praised our 3-shot inverter component, which merged heat-resistant PEEK, EMI-shielding plastic, and a silicone gasket, reducing assembly time by 50%. These examples show multi-shot injection molding solves industry-specific complexity.

Quality Assurance for Complex Multi-Shot Injection Molding

We implement rigorous quality checks to ensure complex multi-shot injection molding parts meet specifications, with 100% inspection protocols for critical features. Automated vision systems check for defects like incomplete bonding, flash, or misalignment between material zones, while CMMs verify dimensional accuracy on a statistically significant sample. For example, a 3-shot medical device undergoes leak testing (to 10 psi) and bond strength testing (200+ psi) to ensure fluid-tight performance. We also conduct environmental testing—thermal cycling, chemical exposure, vibration—to validate durability, critical for complex parts in harsh conditions. A validation study on our 2-shot automotive sensor showed no performance degradation after 1,000 hours of heat and humidity testing. Our ISO 9001, IATF 16949, and ISO 13485 certifications ensure consistent quality across industries. This quality assurance gives clients confidence that even the most complex multi-shot parts perform reliably.