Material Selection for Sterilizable Multi-Shot Injection Molding

We prioritize medical-grade materials in multi-shot injection molding to ensure components withstand rigorous sterilization while maintaining functionality. Our go-to combinations include polycarbonate (PC) or cyclo-olefin polymer (COP) for rigid structures, paired with liquid silicone rubber (LSR) for flexible seals—both materials resist autoclaving, ethylene oxide (EtO), and gamma radiation. For example, a 2-shot syringe plunger uses PC for structural integrity and LSR for a tight, lubricious seal, maintaining performance after 100+ autoclave cycles at 134°C. We also select materials with low extractables to meet ISO 10993 biocompatibility standards, critical for devices contacting bodily fluids. A recent project for a surgical tool handle combined PEEK (resistant to chemical sterilants) with a colored TPE overmold, proving multi-shot injection molding can merge sterility with ergonomic design. These material pairings ensure medical components remain reliable through repeated sterilization.

Sterilization Compatibility in Multi-Shot Injection Molding

Our multi-shot injection molding processes are engineered to produce components that maintain dimensional stability and bond integrity through aggressive sterilization methods. We test each material combination under real-world sterilization conditions: autoclaving at 134°C/30 psi, EtO exposure, and gamma irradiation up to 50 kGy. For example, a 3-shot IV connector undergoes 50 autoclave cycles, then undergoes leak testing to verify the LSR seal remains intact—a critical check, as even 0.1mm delamination could cause fluid contamination. We also monitor for material degradation, such as yellowing in PC or brittleness in TPEs, which can compromise performance. A validation study on our multi-shot injection molding surgical stapler components showed less than 0.02mm dimensional change after 100 sterilization cycles, well within medical tolerances. This focus on sterilization compatibility ensures multi-shot components meet the longevity demands of healthcare settings.

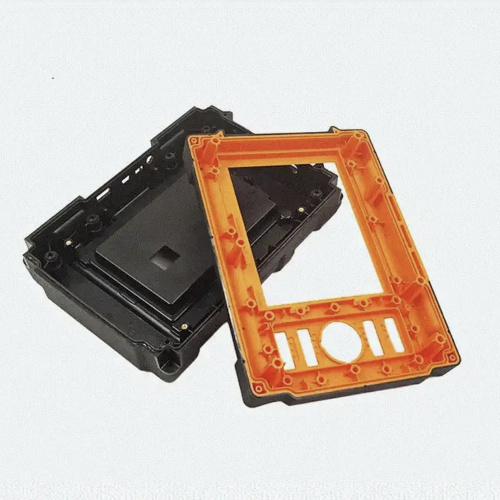

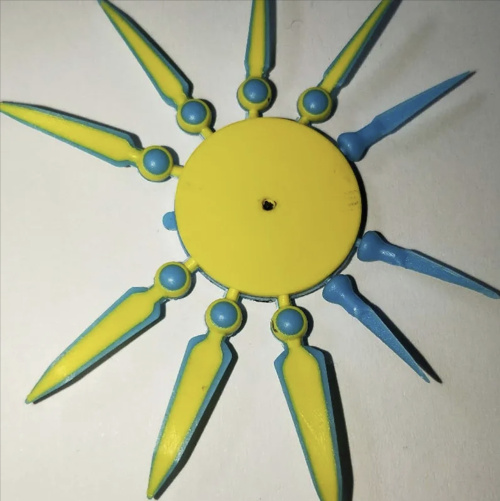

Color-Coding Systems in Multi-Shot Injection Molding for Medical Devices

Multi-shot injection molding enables precise color-coding of medical components, enhancing safety and usability in fast-paced clinical environments. We integrate color pigments into the second or third shot, creating high-contrast indicators without secondary painting—critical for avoiding chipping or chemical leaching. For example, a 2-shot catheter hub uses a clear PC base with a colored TPE ring (red for arterial, blue for venous) to prevent misconnection, with colorfastness tested under sterilization. We also use color to indicate size or dosage: a 3-shot insulin pen cartridge combines a clear body, colored dose markers (green for 100u, yellow for 300u), and a LSR seal, all in one cycle. Our color-matching system ensures consistency across production runs (ΔE < 1.0), meeting FDA requirements for medical device labeling. This color-coding capability makes multi-shot injection molding invaluable for reducing medical errors.

Precision and Tolerance Control in Medical Multi-Shot Injection Molding

Medical devices demand tight tolerances, and our multi-shot injection molding processes deliver consistent precision for critical components. We maintain ±0.01mm dimensional control for features like LSR seal diameters, ensuring a secure fit in devices such as respirator valves or drug delivery ports. For example, a 2-shot endoscope adapter requires the metal insert, PC housing, and LSR O-ring to align within 0.02mm to prevent fluid leakage during procedures. We use in-mold sensors to monitor pressure and temperature in real time, adjusting parameters to compensate for material variations—critical when bonding dissimilar materials like PEEK and LSR. Statistical process control (Cpk ≥ 1.67) ensures stability across production, with 100% CMM inspection for critical dimensions. A recent audit of 5,000 multi-shot surgical instrument components confirmed 99.9% met tolerance requirements, demonstrating our commitment to precision.

Regulatory Compliance in Multi-Shot Injection Molding for Medical Devices

We design our multi-shot injection molding processes to meet strict medical regulatory standards, ensuring traceability and consistency for compliant devices. Our ISO 13485-certified facility maintains detailed records of material lots, process parameters, and inspection results for every batch, enabling full traceability from raw material to finished component. We validate multi-shot processes through process capability studies and design of experiments (DOE), documenting that variables like injection pressure or mold temperature do not affect biocompatibility or performance. For example, a 3-shot medical connector underwent rigorous validation, including 1,000 sterilization cycles and biocompatibility testing (ISO 10993-5), to gain FDA clearance. We also conduct regular internal audits to ensure compliance with FDA 21 CFR Part 820, particularly for process validation and change control. This regulatory focus makes multi-shot injection molding a reliable choice for Class II and III medical devices.

Application Examples of Multi-Shot Injection Molding in Medical Devices

Multi-shot injection molding enables innovative medical devices across specialties, from diagnostics to surgery. In anesthesia, our 2-shot breathing circuit connectors combine rigid PC with LSR seals and color-coded rings, reducing assembly steps by 4 and improving leak resistance. Diagnostic devices use 3-shot components: a test strip housing with a clear PC window, colored TPE grips, and LSR gaskets to protect internal electronics from fluid damage. Surgical tools benefit from ergonomic 2-shot handles—rigid PBT cores with overmolded TPE grips in surgeon-specific colors, reducing hand fatigue during long procedures. A recent breakthrough is a 3-shot wearable biosensor that integrates a rigid substrate, conductive TPE electrodes, and a LSR adhesive layer, enabling continuous monitoring with skin-friendly comfort. These applications demonstrate how multi-shot injection molding advances medical device functionality, safety, and user experience.